Navigating 2025 CHIPS Act: US Auto Semiconductor Boost

Navigating the 2025 CHIPS Act: A $52 Billion Boost for US Automotive Semiconductor Production is currently underway, marking a pivotal moment for domestic manufacturing and supply chain resilience. This significant federal investment aims to re-establish the United States as a global leader in semiconductor fabrication, particularly for the automotive sector.

Understanding the CHIPS Act and its Automotive Focus

The CHIPS and Science Act, enacted in 2022, allocates substantial federal funding to stimulate domestic semiconductor research, development, and manufacturing. While broad in its scope, a significant portion of this investment is now clearly targeting the automotive industry, which faced severe disruptions during the recent global chip shortage.

This strategic focus acknowledges the critical role semiconductors play in modern vehicles, from engine management systems and infotainment to advanced driver-assistance systems (ADAS) and electric powertrains. The automotive sector’s increasing demand for sophisticated chips necessitates a robust and secure domestic supply chain.

Key Provisions Targeting Automotive Production

The Act includes several mechanisms designed to directly benefit automotive semiconductor manufacturing. These range from direct financial incentives to research and development grants, all aimed at reducing reliance on overseas production and fostering innovation within US borders.

- Manufacturing Incentives: Billions are allocated for grants, loans, and loan guarantees to companies building or expanding semiconductor fabrication facilities (fabs) in the US.

- Research and Development: Significant funding supports R&D initiatives focused on next-generation semiconductor technologies relevant to automotive applications.

- Workforce Development: Investment in training programs and educational pathways aims to cultivate a skilled workforce for the burgeoning domestic semiconductor industry.

The $52 Billion Allocation: Breaking Down the Investment

The headline figure of $52 billion represents a comprehensive commitment to revitalizing the US semiconductor industry. This sum is not a single lump-sum payment but rather a multi-faceted allocation distributed across various programs and initiatives over several years. Its impact on 2025 CHIPS Act Automotive production is expected to be profound, laying the groundwork for a more stable future.

Industry experts indicate that a substantial portion of these funds will directly or indirectly bolster the automotive sector. This includes funding for foundries capable of producing older nodes, which are still crucial for many vehicle components, as well as cutting-edge chips for electric vehicles and autonomous driving.

Where the Funds Are Going

The monies are channeled through different government agencies and programs, each with specific objectives. The Department of Commerce, for instance, is overseeing the largest share of the manufacturing incentives. This structured approach ensures that funds are strategically deployed to achieve maximum impact across the semiconductor ecosystem.

- New Fab Construction: Major investments are facilitating the establishment of new state-of-the-art semiconductor manufacturing plants.

- Existing Fab Expansion: Funds are also supporting the modernization and expansion of current facilities to increase production capacity.

- Supply Chain Integration: Efforts are being made to integrate domestic suppliers more effectively into the automotive semiconductor supply chain.

Impact on US Automotive Semiconductor Supply Chains

Prior to the CHIPS Act, the US automotive industry was heavily dependent on foreign semiconductor manufacturers, particularly from Asia. This reliance exposed vulnerabilities, as evidenced by the widespread production shutdowns during the recent chip shortages. The 2025 CHIPS Act Automotive initiatives are directly addressing these structural weaknesses.

By incentivizing domestic production, the Act aims to create a more resilient and geographically diversified supply chain. This means less susceptibility to geopolitical tensions, natural disasters, or pandemics affecting overseas production hubs. Automakers stand to benefit from more stable and predictable access to essential components.

Strengthening Domestic Production Capabilities

The goal is not just to build more fabs, but to build a more comprehensive and robust domestic ecosystem. This includes everything from material suppliers and equipment manufacturers to packaging and testing facilities. A fully integrated domestic supply chain will significantly reduce lead times and improve flexibility for automotive manufacturers.

This shift will also foster greater collaboration between semiconductor companies and automotive original equipment manufacturers (OEMs), leading to more tailored chip designs and faster innovation cycles. The long-term implications for US competitiveness in the global automotive market are substantial.

Driving Innovation in Automotive Technology

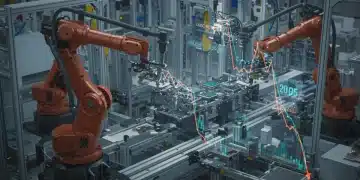

The investment spurred by the 2025 CHIPS Act Automotive focus extends beyond simply increasing production capacity; it is also a catalyst for innovation. With domestic R&D receiving significant funding, American companies are poised to develop the next generation of semiconductors specifically designed for the evolving needs of the automotive industry.

This includes advancements in power semiconductors for electric vehicles, high-performance computing chips for autonomous driving, and secure microcontrollers for connected car features. The proximity of R&D to manufacturing facilities will accelerate the transition from concept to commercialization.

![]()

Key Areas of Technological Advancement

The automotive sector is undergoing a profound transformation, driven by electrification, automation, and connectivity. Each of these trends demands increasingly sophisticated semiconductor solutions. The CHIPS Act funds are strategically aimed at supporting breakthroughs in these critical areas.

- Electric Vehicle Efficiency: Developing more efficient power management chips and robust inverter technology for EVs.

- Autonomous Driving Processors: Creating high-performance, low-power chips capable of handling complex AI and sensor data for self-driving cars.

- Cybersecurity for Connected Cars: Innovating secure semiconductor solutions to protect vehicles from cyber threats.

Challenges and Opportunities for Implementation

While the prospects of the 2025 CHIPS Act Automotive boost are promising, the implementation phase presents its own set of challenges. Building and staffing advanced semiconductor fabs is a complex and capital-intensive undertaking, requiring significant coordination between government, industry, and educational institutions.

One of the primary challenges is the severe shortage of skilled labor in the semiconductor industry. Attracting and training a new generation of engineers, technicians, and manufacturing specialists will be crucial for the success of these initiatives. Furthermore, navigating environmental regulations and securing necessary permits for large-scale construction also requires careful planning.

Overcoming Obstacles and Maximizing Potential

Despite these hurdles, the opportunities are immense. The Act provides a clear framework and financial backing to overcome many of these challenges. Collaborative efforts are already underway to establish new training programs and educational partnerships to build the necessary workforce.

The long-term benefits of a revitalized domestic semiconductor industry, particularly for the automotive sector, far outweigh the immediate complexities. Reduced reliance on foreign supplies, enhanced national security, and sustained economic growth are all within reach if implementation is successful and sustained.

Long-Term Economic and Geopolitical Implications

The strategic investment under the 2025 CHIPS Act Automotive segment carries significant long-term economic and geopolitical implications for the United States. Economically, it promises to create thousands of high-paying jobs, stimulate related industries, and bolster US GDP. It also positions the US at the forefront of a critical technological domain, fostering innovation that can spill over into other sectors.

From a geopolitical perspective, reducing reliance on a concentrated global supply of semiconductors, particularly from regions with potential instability, enhances national security. It provides the US with greater leverage and resilience in an increasingly complex global landscape, ensuring that essential industries like automotive are not held hostage by supply chain disruptions.

Shifting the Global Semiconductor Landscape

This initiative is part of a broader global trend where nations are seeking to onshore critical manufacturing capabilities. The US move is expected to inspire similar actions and potentially reshape the global semiconductor supply chain, fostering a more distributed and resilient network of production hubs worldwide. The competitive dynamics of the industry are set for a significant shift.

Ultimately, the success of the CHIPS Act in the automotive sector will serve as a blueprint for future strategic investments in other critical industries. It underscores a commitment to industrial policy aimed at securing America’s technological and economic future in the 21st century.

| Key Point | Brief Description |

|---|---|

| $52 Billion Investment | Federal funds allocated to boost US semiconductor research, development, and manufacturing. |

| Automotive Focus | Significant portion targets critical chips for modern vehicles, addressing past shortages. |

| Supply Chain Resilience | Aims to reduce reliance on foreign suppliers and create a robust domestic ecosystem. |

| Innovation Catalyst | Supports R&D for next-gen EV, autonomous, and connected car semiconductor technologies. |

Frequently Asked Questions About the CHIPS Act and Automotive Semiconductors

The primary goal is to bolster domestic production of semiconductors essential for modern vehicles, thereby enhancing supply chain resilience and reducing the automotive industry’s vulnerability to global chip shortages and geopolitical disruptions.

While the CHIPS Act allocates $52 billion broadly, a significant portion is directly and indirectly channeled to support automotive semiconductor manufacturing through grants, R&D funding, and workforce development initiatives aimed at this critical sector.

Directly, it’s unlikely to immediately reduce car costs. However, by stabilizing the supply chain and preventing future chip shortages that lead to production cuts, it aims to ensure more consistent vehicle availability and potentially mitigate price increases driven by scarcity.

Automotive vehicles require a wide range, including microcontrollers for engine management, power semiconductors for EVs, sensors for ADAS, and high-performance chips for infotainment and autonomous driving systems. The CHIPS Act supports all these areas.

While some projects are already underway, the full impact of new fabs and expanded production will likely be seen over the next 3-5 years, with significant improvements in supply chain stability and domestic capacity expected by 2025 and beyond.

Looking Ahead

The unfolding developments surrounding the 2025 CHIPS Act Automotive investments are poised to redefine the landscape of semiconductor manufacturing and its profound implications for the US auto industry. As new fabrication plants break ground and research initiatives gain momentum, stakeholders must closely monitor the allocation of funds and the progress of these ambitious projects. The coming months will reveal critical milestones, particularly regarding workforce development and the integration of new domestic capacities into existing automotive supply chains. This strategic push is not merely about economic stimulus but about securing a vital component of future technological and national security.