3D Printing in US Auto: 4% Cost Cut by 2025

The integration of additive manufacturing, specifically 3D printing, into United States automotive production is poised to achieve a 4% reduction in overall manufacturing costs by 2025, according to recent industry analyses.

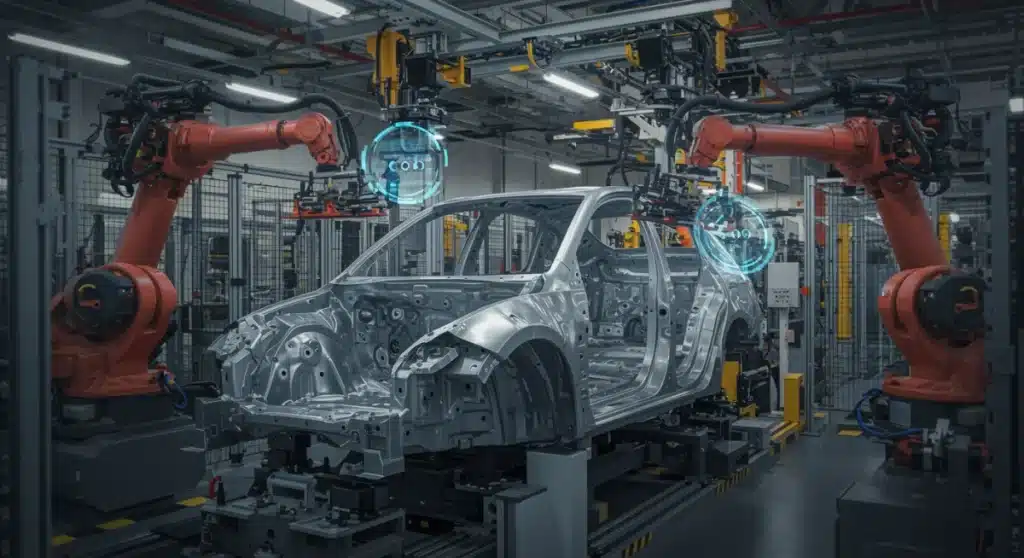

Breaking news from the automotive sector highlights a significant shift: the economic implications of 3D printing adoption in US auto production by 2025, reducing costs by 4%. This development is not merely a technological upgrade but a fundamental re-evaluation of how vehicles are made, promising substantial financial benefits across the industry. What does this mean for manufacturers, consumers, and the future of American car-making?

The Drive Towards Cost Efficiency in Auto Production

The US automotive industry is constantly seeking innovative methods to enhance efficiency and reduce expenditures. With fierce global competition and increasing demands for sustainable practices, manufacturers are turning to advanced technologies. 3D printing, also known as additive manufacturing, has emerged as a frontrunner in this quest, offering unprecedented opportunities to streamline production and cut costs.

Industry experts and recent reports from leading consulting firms, such as McKinsey & Company and Deloitte, indicate that a 4% cost reduction is an achievable target by 2025. This projection is based on the increasing maturity of 3D printing technologies, the expanding range of printable materials, and the growing expertise within the automotive workforce. The shift is not just theoretical; it’s already underway in various facets of the production process.

Revolutionizing Prototyping and Tooling

One of the immediate and most impactful applications of 3D printing in the automotive sector has been in rapid prototyping and the creation of custom tooling. Traditionally, these processes were time-consuming and expensive, requiring specialized machinery and skilled labor for each iteration. Additive manufacturing fundamentally changes this dynamic.

- Faster Iteration Cycles: Engineers can quickly print and test multiple design variations for new parts, drastically shortening development timelines.

- Reduced Tooling Costs: Custom jigs, fixtures, and molds can be 3D printed on-demand, eliminating the need for expensive conventional manufacturing.

- Design Freedom: Complex geometries and lightweight structures, previously difficult or impossible to manufacture, become feasible, leading to optimized part performance.

This acceleration in the design and prototyping phase directly translates into significant cost savings, as fewer resources are expended on trial-and-error, and products reach the market faster. The ability to produce highly customized tools internally also reduces reliance on external suppliers, further controlling costs and supply chain risks.

Supply Chain Optimization Through Localized Production

The global automotive supply chain is notoriously complex and vulnerable to disruptions, as evidenced by recent events. 3D printing offers a compelling solution by enabling localized production and reducing dependence on distant suppliers. This strategic shift not only enhances resilience but also contributes significantly to cost reduction targets.

By producing parts closer to assembly plants or even on-site, manufacturers can drastically cut down on shipping costs, import duties, and lead times. This localized approach minimizes inventory holding costs and reduces the risk of stockouts, which can halt production lines and incur substantial financial penalties. The ability to print parts as needed, rather than relying on large-batch overseas orders, represents a lean manufacturing ideal finally within reach.

On-Demand Manufacturing of Spare Parts

The aftermarket and spare parts sector is another area ripe for disruption by 3D printing. The traditional model involves maintaining vast inventories of parts for older vehicle models, which ties up capital and incurs storage costs. With additive manufacturing, spare parts can be printed on-demand, eliminating the need for extensive warehouses.

- Reduced Inventory Costs: Manufacturers no longer need to stock large quantities of every possible spare part.

- Faster Delivery: Parts can be printed and dispatched quickly, reducing vehicle downtime for repair.

- Obsolescence Management: Even parts for discontinued models can be produced, extending the lifespan of vehicles and improving customer satisfaction.

This paradigm shift in spare parts logistics contributes directly to the projected 4% cost reduction by 2025. It also provides a competitive advantage in customer service and sustainability, as fewer parts end up as waste due to obsolescence.

Material Innovation and Lightweighting

The continuous development of advanced materials compatible with 3D printing is a critical factor driving its economic impact. New polymers, metal alloys, and composites are enabling the creation of parts that are not only lighter but also stronger and more durable than their traditionally manufactured counterparts. This lightweighting directly translates to fuel efficiency gains and reduced material consumption.

For example, topologically optimized designs, which 3D printing excels at producing, can create structures that use the minimum amount of material necessary while maintaining or even improving structural integrity. This engineering feat results in significant material cost savings during production and long-term operational cost savings for vehicle owners due to improved fuel economy.

Advanced Composite Integration

The auto industry is increasingly focused on reducing vehicle weight to meet stringent fuel efficiency and emissions standards. 3D printing allows for the integration of advanced composites and multi-material designs in ways that traditional manufacturing cannot. This leads to parts that are not only lighter but also possess superior performance characteristics.

The ability to precisely control the internal structure of a part during the 3D printing process means that engineers can design for specific stress loads, placing material only where it is truly needed. This contrasts sharply with subtractive manufacturing, where material is removed from a solid block, often resulting in waste and suboptimal weight distribution.

Challenges and Investment for Widespread Adoption

While the benefits are clear, achieving the projected 4% cost reduction by 2025 is not without its challenges. Significant investment in new equipment, workforce training, and research and development is required. Automakers must integrate these new technologies into existing production lines, which demands careful planning and execution.

The scalability of 3D printing for mass production remains a key hurdle for some applications. While ideal for prototyping, tooling, and specialized components, printing every single part of a car at high volume is still economically unfeasible for many components. However, advancements in print speed, material costs, and post-processing techniques are rapidly addressing these limitations.

Overcoming Integration Complexities

- Workforce Upskilling: Training engineers and technicians in additive manufacturing processes and design for additive manufacturing (DfAM) is crucial.

- Standardization: Developing industry standards for 3D printed automotive parts will ensure quality, reliability, and interoperability.

- Material Development: Continued innovation in high-performance, cost-effective, and automotive-grade printable materials is essential.

Despite these challenges, the trajectory for 3D printing in US auto production clearly points towards increased adoption. Leading manufacturers are already heavily investing, recognizing the long-term strategic advantages and the immediate cost-saving potential.

Impact on US Manufacturing and Job Market

The widespread adoption of 3D printing in the US automotive industry will have profound implications beyond just cost reduction. It is expected to revitalize domestic manufacturing, creating new types of jobs and fostering innovation within the country. By enabling localized production, it reduces reliance on overseas factories and strengthens the national industrial base.

While some traditional manufacturing jobs may evolve, the demand for skilled workers in areas like additive manufacturing engineering, machine operation, and material science is expected to grow. This shift could lead to a more resilient and technologically advanced manufacturing sector in the United States, positioning it at the forefront of global automotive innovation.

Reshaping the Automotive Workforce

The changes brought by 3D printing necessitate a re-evaluation of the skills required in the automotive workforce. Educational institutions and vocational training programs will need to adapt to prepare the next generation of manufacturing professionals.

- Design for Additive Manufacturing (DfAM): Engineers must learn how to design parts specifically for 3D printing to maximize its benefits.

- Machine Operation and Maintenance: Skilled technicians are needed to operate and maintain complex 3D printing systems.

- Quality Control and Certification: New protocols for inspecting and certifying 3D printed components are being developed.

This transformation is not about replacing human labor with machines entirely, but rather about augmenting human capabilities with advanced tools, leading to higher-value, more specialized roles within the manufacturing ecosystem.

The Competitive Edge of Early Adopters

Automakers who are proactive in adopting and integrating 3D printing technologies are poised to gain a significant competitive advantage. The projected 4% cost reduction by 2025 is a substantial figure in an industry known for its tight margins. Early adopters will be able to offer more competitively priced vehicles, develop new products faster, and respond more agilely to market demands.

Beyond direct cost savings, the ability to innovate rapidly and customize production will differentiate these manufacturers. As consumer preferences shift towards personalization and efficiency, 3D printing offers the flexibility needed to meet these evolving expectations. This technological edge could redefine market leadership in the coming years.

The strategic implementation of 3D printing is not just about incremental improvements; it’s about fundamentally rethinking the manufacturing paradigm. Companies that embrace this change will be better positioned for long-term success, driving innovation and efficiency across their operations and ultimately benefiting consumers through more advanced and affordable vehicles.

| Key Aspect | Brief Description |

|---|---|

| Cost Reduction Target | US auto production aims for a 4% cost reduction by 2025 through 3D printing adoption. |

| Key Application Areas | Prototyping, tooling, and on-demand spare parts manufacturing are primary drivers. |

| Supply Chain Impact | Localized production reduces reliance on distant suppliers and inventory costs. |

| Future Workforce | New jobs and specialized skills in additive manufacturing will be in demand. |

Frequently Asked Questions About 3D Printing in Auto

3D printing reduces costs by accelerating prototyping, creating custom tooling in-house, optimizing supply chains through localized manufacturing, and lowering inventory needs for spare parts. It also enables lightweighting of components, leading to material savings and improved vehicle fuel efficiency.

The areas benefiting most include rapid prototyping, where design iterations are faster; custom tooling and fixtures, reducing external costs; and the production of complex, lightweight components. On-demand manufacturing of spare parts also offers significant logistical and inventory cost savings.

Yes, industry analysts and consulting firms project the 4% cost reduction as realistic. This is based on advancements in 3D printing technology, expanded material options, and increasing industry expertise, coupled with strategic investments by major automakers in integrating these solutions.

Key challenges include the need for significant capital investment in new equipment, training the workforce in additive manufacturing skills, developing industry-wide standards for 3D printed parts, and continued advancements in materials and print speeds for mass production scalability.

While some job roles may evolve, 3D printing is expected to create new, specialized jobs in additive manufacturing engineering, machine operation, and material science. It will foster a more technologically advanced and resilient domestic manufacturing sector, requiring a skilled workforce adapted to new production paradigms.

Looking Ahead: The Future of Auto Manufacturing

The confirmed trajectory for 3D printing integration in US auto manufacturing, with projections targeting a 4% production cost reduction by 2025, represents far more than a simple operational gain. It marks the beginning of a system-level transformation, where additive manufacturing evolves from a supplementary process to a core pillar of domestic automotive production strategy. This shift has the potential to decentralize traditional supply chains, reduce tooling lead times, and significantly improve material efficiency—elements that directly affect profitability and national manufacturing resilience.

As US automakers accelerate adoption, the next phase will involve scaling industrial-grade 3D printing capabilities, expanding the use of high-performance engineering materials, and integrating digital twin simulation into factory planning. Industry analysts highlight that manufacturing flexibility is becoming as valuable as production volume. Solutions like high-precision metal mold printing, already under study by scientific institutions and covered em iniciativas como as destacadas pela Newswise on breakthrough 3D mold printing applications, demonstrate how the technology is moving from prototype experimentation to full-scale production relevance.

Looking forward, the competitive edge will increasingly favor automakers that align additive manufacturing technology, workforce transformation, and regionalized supply chain strategies. Those who move early to secure materials expertise, automation infrastructure, and specialized labor pipelines will be best positioned to redefine cost structures, reduce import dependency, and strengthen domestic manufacturing autonomy. The future of the US automotive sector will be shaped not just by electrification and software integration but by how efficiently it harnesses industrial 3D printing to build a more agile and future-proof production ecosystem.