5 Emerging Technologies Revolutionizing US Auto Plants by 2026

By 2026, five emerging technologies are poised to fundamentally transform US auto plants, driving unprecedented efficiency, flexibility, and sustainability across the automotive manufacturing landscape.

US Auto Plant Technologies are rapidly evolving, with significant advancements expected to reshape manufacturing processes by 2026. This article delves into the five key emerging technologies that will revolutionize US automotive production, offering insider knowledge on their impact and what industry players need to monitor next.

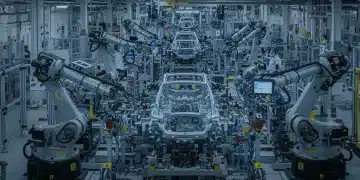

The Rise of Advanced Robotics and Collaborative Automation

Advanced robotics and collaborative automation are no longer futuristic concepts but are becoming integral to daily operations in US auto plants. These systems promise to enhance precision, accelerate production cycles, and improve worker safety by taking on repetitive or hazardous tasks. The integration of smarter robots that can learn and adapt is a game-changer for manufacturing flexibility.

The evolution from traditional industrial robots to collaborative robots, or ‘cobots,’ marks a significant shift. Cobots are designed to work alongside human operators, sharing workspaces and assisting with complex assembly tasks. This collaboration minimizes the need for extensive safety caging, streamlining plant layouts and fostering a more dynamic work environment.

Enhanced Precision and Speed

Modern robots, equipped with advanced sensors and artificial intelligence, can perform tasks with unparalleled precision, reducing errors and waste. Their speed in repetitive operations significantly cuts down production times, allowing manufacturers to meet increasing demand more efficiently. This technological leap enables the production of higher-quality vehicles at a faster pace.

- Accelerated Assembly: Robots handle intricate parts alignment and fastening with consistent accuracy.

- Improved Quality Control: Automated inspection systems detect minute flaws invisible to the human eye.

- Reduced Downtime: Predictive maintenance for robots minimizes unexpected operational halts.

The strategic deployment of these advanced systems is critical for US auto plants aiming to stay competitive globally. By 2026, the seamless integration of human and robotic efforts will be a hallmark of efficient automotive manufacturing.

Artificial Intelligence and Machine Learning for Optimization

Artificial Intelligence (AI) and Machine Learning (ML) are set to become the brains behind the brawn in US auto plants, moving beyond simple task automation to complex decision-making and optimization. These technologies analyze vast datasets from production lines, identifying patterns and predicting potential issues before they arise, thereby drastically improving efficiency and reducing costs.

From supply chain management to quality assurance, AI and ML algorithms are capable of processing information at speeds and scales impossible for humans. This enables real-time adjustments to production schedules, predictive maintenance of machinery, and even the optimization of energy consumption within the plant. The goal is a truly autonomous and self-optimizing factory floor.

Predictive Maintenance and Quality Assurance

One of the most immediate benefits of AI in manufacturing is predictive maintenance. ML models analyze sensor data from machines to forecast equipment failure, allowing for proactive repairs rather than reactive ones. This dramatically reduces costly downtime and extends the lifespan of machinery. Similarly, AI-powered vision systems can inspect products for defects with superior accuracy and speed, ensuring higher quality output.

- Proactive Repairs: AI predicts machine failures, enabling planned maintenance.

- Defect Detection: ML algorithms identify anomalies in components and finished products.

- Supply Chain Optimization: AI forecasts demand and manages inventory to prevent bottlenecks.

The strategic application of AI and ML will enable US auto plants to minimize waste, optimize resource allocation, and produce vehicles of consistently high quality, solidifying their position in the global market by 2026.

Additive Manufacturing (3D Printing) for Prototyping and Production

Additive manufacturing, commonly known as 3D printing, is evolving beyond rapid prototyping to become a viable method for producing functional components directly on the assembly line. This technology offers unparalleled design flexibility, allowing for complex geometries and lightweight structures that are difficult or impossible to achieve with traditional manufacturing methods. Its integration into US auto plants is expected to streamline supply chains and reduce material waste.

The ability to print parts on-demand means less reliance on external suppliers for certain components, reducing lead times and inventory costs. Furthermore, 3D printing facilitates the customization of parts, which is increasingly valuable in an automotive market demanding greater personalization. This shift towards localized, on-demand production represents a significant paradigm change for the industry.

Rapid Prototyping and Customization

While 3D printing has long been used for prototyping, its advancements now allow for the creation of end-use parts made from a variety of robust materials, including metals and high-performance polymers. This capability supports rapid iteration in design and allows for the production of specialized tools and fixtures in-house, further speeding up the production process and reducing reliance on external vendors.

The potential for mass customization through additive manufacturing is immense. Imagine car buyers selecting unique interior components or specialized performance parts that are then 3D printed to order. This level of personalization could redefine the customer experience and open new revenue streams for manufacturers.

By 2026, 3D printing will be a cornerstone of flexible manufacturing, enabling US auto plants to quickly adapt to market changes and offer highly customized products while maintaining cost efficiency.

Industrial Internet of Things (IIoT) for Connected Operations

The Industrial Internet of Things (IIoT) is creating a vast, interconnected network of machines, sensors, and operational systems within US auto plants. This pervasive connectivity enables real-time data collection, monitoring, and analysis across the entire production floor, providing unprecedented visibility into manufacturing processes. The insights gained from IIoT data are crucial for optimizing performance, identifying inefficiencies, and enhancing overall operational control.

Every piece of equipment, from robotic arms to conveyor belts, can be outfitted with sensors that continuously feed data into a central system. This data stream allows managers to track production metrics, monitor asset health, and even manage energy consumption from a single dashboard. The result is a highly responsive and data-driven manufacturing environment.

Real-time Monitoring and Data-Driven Decisions

With IIoT, plant managers can make informed decisions based on live data, rather than relying on outdated reports. This real-time insight allows for immediate adjustments to production parameters, preventing bottlenecks and ensuring smooth operations. The ability to remotely monitor and control equipment also adds a layer of flexibility and responsiveness, especially in complex global supply chains.

- Enhanced Visibility: Comprehensive overview of all production processes in real-time.

- Optimized Resource Use: Better management of energy, materials, and personnel.

- Predictive Analytics: Leveraging data to foresee and address potential operational issues.

The pervasive adoption of IIoT will transform US auto plants into smart factories by 2026, where every component of the manufacturing process is intelligently connected and optimized for maximum output and efficiency.

Augmented Reality (AR) and Virtual Reality (VR) for Training and Design

Augmented Reality (AR) and Virtual Reality (VR) are set to revolutionize how US auto plant employees are trained, how vehicles are designed, and how maintenance is performed. These immersive technologies offer highly interactive and realistic simulations, significantly reducing the learning curve for new processes and enhancing the precision of complex tasks. The applications span from virtual walkthroughs of new plant layouts to hands-on training for intricate assembly procedures.

For training, AR and VR provide a safe and cost-effective environment to practice skills without disrupting active production lines or risking damage to expensive equipment. In design, VR allows engineers to virtually explore and refine vehicle prototypes in a collaborative 3D space, identifying design flaws and making improvements before physical models are even built. AR, on the other hand, overlays digital information onto the real world, assisting technicians with real-time instructions during assembly or repair.

Immersive Training and Collaborative Design

AR headsets can guide technicians step-by-step through complex repairs or assembly processes, displaying digital instructions directly onto the physical object they are working on. This reduces errors and speeds up task completion. VR environments enable global design teams to collaborate on new vehicle models as if they were in the same room, accelerating the design cycle and fostering innovation.

- Skill Development: VR simulations for complex machinery operation and assembly.

- Remote Assistance: AR allows experts to guide on-site technicians from anywhere.

- Ergonomic Design: VR helps identify and optimize workstation layouts for worker comfort and efficiency.

By 2026, AR and VR will be indispensable tools in US auto plants, enhancing worker capabilities, accelerating design processes, and ensuring a higher standard of operational excellence.

Blockchain for Supply Chain Transparency and Security

Blockchain technology, while often associated with cryptocurrencies, offers transformative potential for US auto plants by providing immutable and transparent records for supply chain management. Its decentralized ledger system can track every component from its origin to the final assembly line, ensuring authenticity, ethical sourcing, and compliance with regulations. This enhanced transparency is crucial for an industry grappling with complex global supply chains and increasing consumer demand for accountability.

The automotive supply chain is notoriously intricate, involving thousands of suppliers across multiple tiers. Blockchain can streamline this complexity by creating a shared, tamper-proof record of all transactions and movements. This not only improves efficiency but also significantly boosts security against counterfeit parts and reduces the risk of fraud. By 2026, blockchain will be a key enabler of trust and efficiency in automotive logistics.

Ensuring Authenticity and Traceability

With blockchain, each component’s journey can be meticulously recorded, providing an unbreakable chain of custody. This allows manufacturers to instantly verify the authenticity of parts, trace back any defective components to their source, and ensure that all materials meet environmental and labor standards. This level of traceability is invaluable for quality control, recalls, and meeting stringent regulatory requirements.

- Counterfeit Prevention: Securely authenticating parts and materials.

- Ethical Sourcing: Verifying the origin and compliance of raw materials.

- Streamlined Audits: Providing transparent and easily verifiable transaction histories.

The integration of blockchain will provide US auto plants with an unprecedented level of supply chain visibility and integrity, fostering greater trust among consumers and partners, and securing the future of automotive manufacturing.

Technology |

Key Impact |

|---|---|

Advanced Robotics |

Enhances precision, speed, and worker safety in assembly. |

AI & Machine Learning |

Optimizes production, enables predictive maintenance, and improves quality. |

Additive Manufacturing |

Facilitates rapid prototyping, customization, and on-demand parts production. |

Industrial IoT |

Provides real-time data for connected operations and informed decision-making. |

Frequently Asked Questions About Auto Plant Technologies

Advanced robotics will likely shift job roles, not eliminate them entirely. While robots handle repetitive tasks, new positions in programming, maintenance, and oversight of these complex systems will emerge, requiring a re-skilling of the workforce.

The primary benefits include enhanced predictive maintenance, leading to reduced downtime, optimized production schedules, improved quality control through automated inspection, and more efficient resource allocation across the plant operations.

While still primarily used for prototyping and specialized components, advancements in materials and speed are rapidly making 3D printing viable for mass-customized parts and even some end-use components in US auto plants, especially for complex geometries.

IIoT improves efficiency by providing real-time data from interconnected machines, enabling predictive maintenance, optimizing energy consumption, and allowing for immediate adjustments to production flows, minimizing bottlenecks and waste.

AR/VR will revolutionize training for complex tasks, facilitate collaborative design and prototyping, and provide real-time assistance for maintenance and assembly, drastically enhancing accuracy, speed, and safety for workers in US auto plants.

Looking Ahead: The Integrated Future of US Auto Manufacturing

The integration of these five emerging technologies will not occur in isolation; rather, their combined synergy will forge a new paradigm for US auto plants by 2026. This holistic transformation will create highly efficient, flexible, and sustainable manufacturing ecosystems capable of responding to dynamic market demands and fostering innovation at an unprecedented pace. The automotive industry is on the cusp of a technological revolution that promises to redefine how vehicles are made, from conception to final assembly, ensuring the US remains at the forefront of global automotive production.