Robotics Integration Cuts Auto Plant Downtime by 12% in US

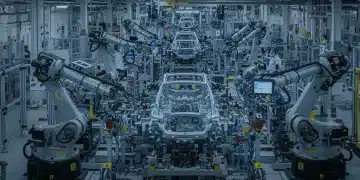

New robotics integration is significantly reducing production line downtime by 12% in US auto plants, according to recent industry reports. This advancement promises enhanced efficiency, lower operational costs, and a stronger competitive position for American automotive manufacturing.

How New Robotics Integration is Reducing Production Line Downtime by 12% in US Auto Plants (INSIDER KNOWLEDGE) is currently a game-changer, reshaping manufacturing landscapes across the nation. This significant reduction in downtime is not merely an incremental improvement; it signals a fundamental shift in operational paradigms, directly impacting productivity, cost-efficiency, and global competitiveness for American automotive giants.

The Dawn of a New Era in Automotive Manufacturing

The US automotive sector is witnessing a transformative period, largely driven by advanced robotics. This integration is moving beyond simple automation, delving into sophisticated systems that predict, prevent, and rapidly resolve operational disruptions. The 12% reduction in production line downtime is a testament to these evolving capabilities, directly translating into millions of dollars saved and increased output capacity.

For decades, downtime has been the bane of manufacturing, a silent drain on resources and productivity. Unexpected equipment failures, maintenance cycles, and retooling processes have historically halted production, leading to missed targets and escalating costs. The current wave of robotics integration, however, is tackling these challenges head-on, deploying intelligent solutions that keep lines moving.

Predictive Maintenance and Smart Diagnostics

- AI-Powered Sensors: Robots equipped with advanced sensors and AI algorithms continuously monitor their own performance and that of surrounding machinery, detecting anomalies before they escalate into failures.

- Real-time Data Analysis: Data streams from robotic systems are analyzed in real-time to identify patterns indicative of potential breakdowns, enabling proactive maintenance scheduling.

- Automated Diagnostics: When issues do arise, robots can often self-diagnose problems, pinpointing the exact component requiring attention, thereby reducing troubleshooting time.

This proactive approach minimizes unscheduled stops, a critical factor in the impressive 12% downtime reduction. By shifting from reactive repairs to predictive interventions, auto plants ensure a smoother, more consistent flow of production, optimizing resource allocation and reducing the need for costly emergency repairs.

Enhancing Efficiency Through Collaborative Robotics

The impact of robotics on downtime reduction extends beyond predictive maintenance. Collaborative robots, or cobots, are playing a pivotal role in optimizing various stages of the production process, from assembly to quality control. These intelligent machines work seamlessly alongside human operators, enhancing precision and speed while minimizing errors that could lead to production halts.

Cobots are designed for flexibility and ease of integration, allowing US auto plants to quickly reconfigure production lines for new models or process variations. This adaptability significantly reduces the downtime traditionally associated with retooling and line adjustments. Their ability to handle repetitive or ergonomically challenging tasks frees human workers to focus on more complex problem-solving and oversight roles, further contributing to overall operational resilience.

Streamlined Operations and Reduced Human Error

- Precision Assembly: Robots perform repetitive tasks with unparalleled accuracy, minimizing defects that would otherwise require rework or cause line stoppages.

- Automated Material Handling: Robotic systems manage the flow of materials and components, ensuring they are delivered to the right place at the right time, preventing bottlenecks.

- Ergonomic Support: Cobots assist in lifting heavy components or performing tasks in difficult-to-reach areas, reducing worker fatigue and the potential for human-induced errors or accidents.

By integrating these collaborative systems, US auto plants are creating more robust and less error-prone production environments. The synergy between human ingenuity and robotic precision is proving to be a powerful formula for sustained uptime and enhanced manufacturing quality.

The Economic Imperative: Cost Savings and Competitive Edge

The 12% reduction in production line downtime directly translates into substantial economic benefits for US auto manufacturers. Fewer interruptions mean higher output, lower labor costs associated with idle time, and reduced expenses for emergency repairs. This improved efficiency is crucial for maintaining a competitive edge in a global market characterized by intense competition and fluctuating demands.

Beyond the immediate cost savings, enhanced uptime allows companies to meet production targets more reliably, improving supply chain predictability and customer satisfaction. It also frees up capital that can be reinvested into research and development, further innovation, or workforce training, creating a virtuous cycle of growth and technological advancement within the industry.

Financial Impact and Market Position

The financial implications are profound. A 12% reduction in downtime can equate to millions of dollars annually for large auto plants, impacting everything from quarterly earnings to long-term investment strategies. This not only strengthens the financial health of individual companies but also bolsters the overall US automotive manufacturing base, making it more resilient against economic shifts and international pressures.

Furthermore, the ability to produce vehicles more consistently and efficiently allows US manufacturers to better compete with global rivals, ensuring that the American automotive industry remains a powerhouse of innovation and production. This competitive advantage is vital for job creation and economic stability in regions heavily dependent on auto manufacturing.

Addressing Challenges in Robotics Integration

While the benefits of robotics integration are clear, the journey to achieving a 12% downtime reduction has not been without its challenges. Implementing advanced robotic systems requires significant upfront investment, specialized technical expertise, and a willingness to adapt existing workflows. Companies must navigate complex integration processes, ensuring seamless communication between new robots and legacy systems.

Moreover, the cybersecurity implications of highly connected robotic networks require robust protective measures. Data integrity and system security are paramount to prevent malicious attacks or accidental breaches that could compromise production or intellectual property. Training the workforce to operate and maintain these sophisticated systems is also a continuous effort, necessitating ongoing investment in education and skill development.

Key Hurdles and Solutions

- Initial Investment: High capital expenditure for purchasing and integrating advanced robotics. Solutions involve phased implementation, government incentives, and strategic partnerships.

- Technical Expertise: Shortage of skilled technicians capable of programming, operating, and maintaining complex robotic systems. Addressed through internal training programs, collaborations with educational institutions, and hiring specialized talent.

- System Compatibility: Integrating new robots with diverse existing manufacturing infrastructure. Overcome by adopting open standards, modular designs, and leveraging integration platforms that facilitate communication between disparate systems.

- Cybersecurity Risks: Protecting interconnected robotic networks from cyber threats. Mitigated through robust cybersecurity protocols, regular system audits, and continuous threat monitoring.

Despite these challenges, the overwhelming benefits associated with reduced downtime and increased efficiency are compelling US auto plants to overcome these obstacles, demonstrating a clear commitment to technological advancement and operational excellence.

The Role of Data Analytics and AI in Sustained Uptime

At the core of this 12% downtime reduction is the sophisticated application of data analytics and artificial intelligence. Modern robotic systems are not just performing tasks; they are generating vast amounts of operational data. This data, when analyzed effectively, provides invaluable insights into machine performance, production bottlenecks, and potential areas for improvement.

AI algorithms are capable of processing this complex data at speeds and scales impossible for human analysis. They can identify subtle patterns and correlations that predict equipment failure days or weeks in advance, allowing maintenance teams to intervene proactively. This shift from reactive maintenance to intelligent, predictive maintenance is a cornerstone of the current success in minimizing production interruptions.

Leveraging Big Data for Operational Excellence

The continuous feedback loop between robotic operations and data analysis ensures ongoing optimization. As more data is collected, AI models become more refined, leading to even more accurate predictions and more efficient resource allocation. This iterative process of learning and improvement is critical for sustaining and even further enhancing uptime achievements.

Furthermore, AI-driven analytics can optimize production schedules, manage inventory levels more effectively, and even recommend adjustments to robot programming to improve efficiency. This comprehensive approach to data utilization is transforming how auto plants operate, making them smarter, more responsive, and significantly more productive.

Future Outlook: Beyond the 12% Downtime Reduction

The current achievement of a 12% downtime reduction is just the beginning. The future of robotics integration in US auto plants promises even greater efficiencies and further reductions in operational interruptions. Advancements in areas such as swarm robotics, self-learning AI, and advanced human-robot interfaces are set to unlock new levels of productivity and flexibility.

As robotic systems become more autonomous and capable of complex decision-making, their ability to self-optimize and recover from minor disruptions will only grow. The integration of augmented reality (AR) and virtual reality (VR) will further enhance maintenance and training, allowing technicians to diagnose and repair issues with greater speed and accuracy, even remotely.

Emerging Technologies and Their Potential

- Swarm Robotics: Multiple smaller, interconnected robots working in concert to achieve complex tasks, offering redundancy and distributed intelligence to minimize single points of failure.

- Self-Learning AI: Robots that can adapt and improve their performance over time without explicit programming, continually optimizing for efficiency and fault tolerance.

- Advanced HRI: More intuitive and natural human-robot interfaces that streamline collaboration, reduce training times, and enhance overall operational fluidity.

The continuous evolution of robotics and AI will ensure that US auto plants remain at the forefront of manufacturing innovation, setting new benchmarks for efficiency, reliability, and ultimately, competitiveness in the global automotive landscape. The journey towards fully autonomous and self-healing production lines is well underway.

Key Aspect |

Impact on Downtime |

|---|---|

Predictive Maintenance |

Reduces unscheduled stops by anticipating failures through AI-powered monitoring. |

Collaborative Robotics |

Enhances assembly precision and flexibility, minimizing human errors and retooling downtime. |

Data Analytics & AI |

Optimizes processes and identifies inefficiencies, leading to continuous operational improvements. |

Economic Benefits |

Significantly lowers operational costs and boosts competitive advantage for US auto plants. |

Frequently Asked Questions About Robotics in Auto Plants

Robotics reduce downtime through predictive maintenance, real-time diagnostics, and enhanced operational precision. AI-powered sensors monitor equipment health to anticipate failures, while collaborative robots minimize human error and streamline assembly processes, preventing unscheduled stoppages and reworks.

The reduction is largely driven by industrial robots performing welding and assembly, and increasingly by collaborative robots (cobots) working alongside humans. Advanced automation systems with integrated AI and machine learning capabilities are also crucial for predictive maintenance and process optimization.

The primary financial benefits include significant cost savings from fewer emergency repairs, increased production output due to continuous operation, and reduced labor costs associated with idle time. This also enhances the competitive position of US manufacturers globally.

Yes, challenges include high initial investment costs, the need for specialized technical expertise, ensuring compatibility with existing infrastructure, and addressing cybersecurity risks. However, the long-term benefits typically outweigh these initial hurdles, driving continued adoption.

Future advancements are expected in swarm robotics, self-learning AI, and more intuitive human-robot interfaces. These innovations will further enhance autonomy, predictive capabilities, and adaptability of robotic systems, leading to even greater efficiencies and sustained uptime in auto plants.

What this means

The 12% reduction in production line downtime through new robotics integration marks a critical juncture for US auto plants, signaling a robust future for domestic manufacturing. This ongoing evolution underscores a commitment to efficiency and innovation, reshaping operational strategies and reinforcing America’s competitive stance in the global automotive sector. Industry stakeholders should closely monitor further technological advancements and their ripple effects on supply chains and workforce development.