Automated Quality Control Boosts US Auto Production 10%

Next-Gen Manufacturing: Automated Quality Control Systems Boosting US Auto Production by 10% (INSIDER KNOWLEDGE) is revolutionizing the automotive sector, enhancing efficiency and product reliability across the United States.

Next-Gen Manufacturing: Automated Quality Control Systems Boosting US Auto Production by 10% (INSIDER KNOWLEDGE) is shaping today’s agenda, with new details emerging from industry leaders and production data. This significant advancement is not just a technological upgrade but a fundamental shift, promising substantial gains for the nation’s automotive sector.

The Dawn of Precision: Automated Quality Control in US Automotive

The US automotive industry is currently experiencing a transformative phase, driven by the integration of advanced automated quality control systems. These systems are moving beyond traditional inspection methods, employing artificial intelligence, machine learning, and sophisticated robotics to ensure unparalleled precision and consistency in vehicle production.

This technological leap addresses long-standing challenges in manufacturing, particularly the detection of minute defects that human eyes might miss. The immediate impact is a reduction in rework and scrap rates, directly contributing to more efficient production lines and a higher quality end product for consumers. The shift represents a strategic investment in the future competitiveness of American car manufacturing on a global scale.

Key Technologies Driving the Revolution

Several cutting-edge technologies are at the forefront of this quality control revolution, each playing a crucial role in enhancing manufacturing processes:

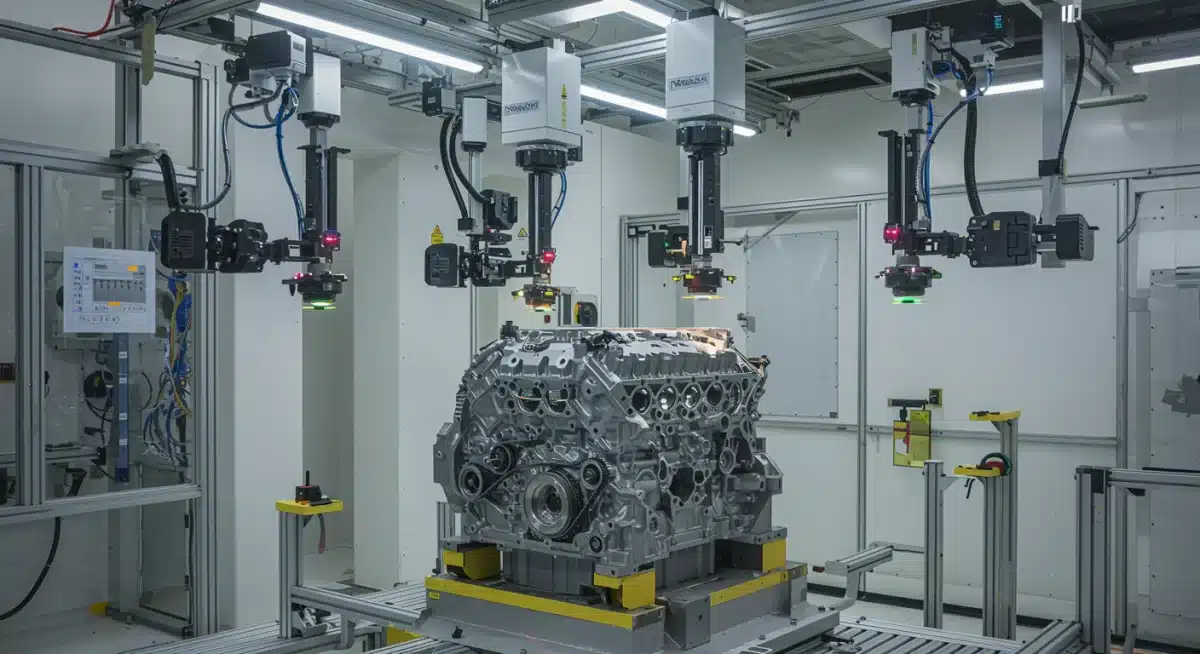

- Advanced Vision Systems: High-resolution cameras combined with AI algorithms detect surface imperfections, misalignments, and assembly errors with extreme accuracy.

- Robotic Inspection: Collaborative robots equipped with sensors perform repetitive and precise inspections, accessing areas difficult for human operators.

- Non-Destructive Testing (NDT): Ultrasonic, eddy current, and X-ray techniques identify internal flaws in materials and components without causing damage.

- Data Analytics and Predictive Maintenance: Real-time data collection from quality checks informs predictive models, allowing for proactive adjustments to manufacturing processes before defects occur.

These integrated systems work in concert, creating a comprehensive quality assurance network that monitors every stage of production. The result is a proactive rather than reactive approach to quality, minimizing waste and maximizing output.

Quantifying the Impact: A 10% Production Boost

Recent reports from leading automotive manufacturers and industry analysts confirm a remarkable trend: the implementation of automated quality control systems is directly correlated with an average 10% boost in US auto production efficiency. This isn’t just about making more cars; it’s about making more high-quality cars, faster and more consistently.

The increase stems from several factors. Reduced downtime due to fewer defects requiring rework is a primary driver. Automated systems can operate continuously with minimal human intervention, maintaining consistent inspection speeds and accuracy. This translates into higher throughput and a more predictable production schedule, crucial for meeting market demands.

Furthermore, the data collected by these systems provides invaluable feedback to engineering and design teams. This iterative improvement cycle means that not only are current production lines more efficient, but future vehicle designs can also be optimized for manufacturability and quality from the outset. This holistic approach underpins the sustained growth observed within the sector.

Efficiency Gains Across the Production Line

The 10% production increase is a composite of improvements seen across various stages of the automotive manufacturing process:

- Stamping and Body Shop: Automated optical inspection (AOI) identifies panel inconsistencies and welding defects early, preventing costly issues downstream.

- Paint Shop: Robotic systems with specialized sensors ensure uniform paint application and detect blemishes, reducing the need for repaints.

- Assembly: Vision systems verify correct component placement, torque application, and electrical connections, ensuring every vehicle meets specifications.

- Powertrain Assembly: Automated testing rigs perform rigorous checks on engines and transmissions, guaranteeing performance and reliability before installation.

These specific applications illustrate how targeted automation in quality control provides incremental gains that collectively lead to the significant overall production boost. The precision and speed of these systems far exceed manual capabilities, setting new benchmarks for manufacturing excellence.

Insider Knowledge: The Strategic Advantage for US Manufacturers

Beyond the quantitative gains, there’s a strategic, qualitative advantage emerging for US manufacturers embracing these next-gen systems. This insider knowledge reveals how companies are leveraging automated quality control not just for efficiency but as a core differentiator in a competitive global market. The ability to guarantee superior product quality consistently builds brand trust and customer loyalty, which are invaluable assets.

Companies are also finding that these systems provide a wealth of data that, when properly analyzed, can unlock further optimizations. This includes identifying supplier quality issues, pinpointing design flaws that impact manufacturability, and even predicting potential equipment failures before they occur. This level of insight was previously unattainable, offering a proactive approach to continuous improvement.

Moreover, the adoption of advanced automation attracts top talent in engineering and technology, fostering an environment of innovation. This influx of expertise further strengthens the US position in high-tech manufacturing, creating a virtuous cycle of technological advancement and skilled workforce development.

Challenges and Solutions in Adoption

While the benefits are clear, the transition to fully automated quality control is not without its challenges. Initial investment costs, the need for specialized training, and integrating new systems with legacy infrastructure are significant hurdles. However, forward-thinking manufacturers are addressing these proactively:

- Phased Implementation: Adopting systems incrementally, starting with critical bottlenecks or high-defect areas, helps manage costs and integration complexities.

- Workforce Retraining: Investing in upskilling programs for existing employees to manage and maintain new technologies ensures a smooth transition and retains valuable institutional knowledge.

- Modular System Design: Choosing flexible, modular automated solutions allows for easier integration and scalability, adapting to evolving production needs.

These strategic approaches ensure that the journey towards advanced automated quality control is sustainable and yields maximum returns, solidifying the competitive edge for US automotive producers.

Enhancing Reliability and Customer Satisfaction

The ultimate beneficiaries of these advancements are consumers. Vehicles produced with next-gen automated quality control systems exhibit higher levels of reliability and fewer defects, translating directly into enhanced customer satisfaction. This improved quality reduces warranty claims, strengthens brand reputation, and cultivates a loyal customer base, all critical for long-term success in the automotive industry.

The precision afforded by automated systems means that critical safety components are inspected with an accuracy that surpasses human capability, leading to safer vehicles on the road. This commitment to safety and quality is a powerful selling point and aligns with consumer expectations for modern automobiles.

Furthermore, the consistency in manufacturing quality contributes to a more predictable ownership experience. Fewer unexpected repairs and better long-term performance mean that customers can trust their vehicles, leading to positive word-of-mouth and repeat business. This virtuous cycle of quality, trust, and loyalty is a direct outcome of embracing advanced quality control.

The investment in these technologies is therefore not just about internal efficiency, but about building an enduring relationship with the end-user, ensuring that every vehicle leaving the factory meets the highest standards.

The Role of AI and Machine Learning in Quality Assurance

Artificial intelligence (AI) and machine learning (ML) are the brains behind the brawn of automated quality control systems. These technologies enable systems to learn from vast datasets of production information, identifying patterns and anomalies that might indicate a potential defect before it becomes a problem. This predictive capability is revolutionizing how quality assurance is managed.

AI-powered vision systems, for instance, can be trained to recognize acceptable variations versus critical defects, adapting to new product designs or material changes with minimal recalibration. Machine learning algorithms continuously refine their detection capabilities, becoming more accurate and efficient over time, far exceeding the static programming of earlier automation.

This dynamic learning process allows manufacturers to maintain peak quality levels even as production complexities increase. The ability to make data-driven decisions in real-time, informed by intelligent algorithms, is a cornerstone of the 10% production boost and the overall improvement in product quality.

Predictive Quality and Process Optimization

The integration of AI and ML extends beyond mere defect detection; it enables predictive quality management. By analyzing trends in inspection data, production parameters, and environmental factors, these systems can:

- Anticipate Equipment Malfunctions: Identify subtle changes in machine performance that precede a breakdown, allowing for scheduled maintenance.

- Optimize Process Settings: Suggest adjustments to welding parameters, paint booth temperatures, or assembly sequences to prevent future defects.

- Identify Root Causes: Automatically correlate detected defects with specific stages or machines in the production line, streamlining root cause analysis.

This shift from reactive problem-solving to proactive prevention is a game-changer for manufacturing efficiency and quality. The insights generated by AI and ML allow for continuous process optimization, ensuring that production lines operate at their highest potential and consistently deliver superior vehicles.

Future Outlook: Sustaining Growth and Innovation

Looking ahead, the trajectory for Next-Gen Manufacturing: Automated Quality Control Systems Boosting US Auto Production by 10% (INSIDER KNOWLEDGE) indicates sustained growth and continuous innovation. The current 10% production boost is likely just the beginning, as these technologies continue to evolve and become more deeply integrated into the entire manufacturing ecosystem. Future advancements will likely include even more sophisticated sensor fusion, enhanced AI capabilities for complex decision-making, and greater interoperability between different automated systems.

The focus will remain on achieving zero-defect manufacturing, reducing environmental impact through minimized waste, and fostering a highly skilled workforce capable of managing these advanced operations. The US automotive industry is positioning itself as a leader in smart manufacturing, ensuring its long-term viability and global competitiveness.

This ongoing evolution underscores a commitment to not only meeting but exceeding consumer expectations for quality, safety, and performance in every vehicle produced on American soil. The future of automotive manufacturing is undeniably automated, intelligent, and quality-driven.

Key Aspect |

Brief Description > |

|---|---|

Production Boost |

Automated QC systems have led to a 10% increase in US auto production efficiency. |

Key Technologies |

AI, ML, advanced vision systems, and robotics are central to new QC methods. |

Strategic Advantage |

Improved quality and data insights enhance brand trust and market competitiveness. |

Future Outlook |

Continued innovation towards zero-defect manufacturing and smart factories. |

Frequently Asked Questions About Automated Quality Control

▼

Automated quality control systems achieve this boost by significantly reducing defects and rework, minimizing production line downtime, and maintaining consistent inspection speeds. Their ability to operate continuously and provide real-time data for process optimization contributes directly to higher throughput and overall efficiency.

▼

Key technologies include advanced vision systems with AI for defect detection, collaborative robotics for precise inspections, non-destructive testing (NDT) methods like ultrasound, and comprehensive data analytics platforms. Machine learning algorithms continuously enhance the accuracy and predictive capabilities of these systems.

▼

The technology leads to a higher standard of product quality and reliability by detecting minute flaws missed by human inspection. This reduces warranty claims, enhances customer satisfaction, and builds stronger brand trust. It also ensures critical safety components are rigorously checked, resulting in safer vehicles.

▼

Yes, challenges include substantial initial investment costs, the need for specialized training for the workforce, and integrating new systems with existing legacy infrastructure. Manufacturers mitigate these by phased implementation, robust employee retraining programs, and selecting modular, flexible automation solutions.

▼

The long-term outlook is positive, with expectations for sustained growth and continuous innovation. Future developments will focus on achieving zero-defect manufacturing, further integrating AI for complex decision-making, and enhancing interoperability between systems. This positions the US industry as a global leader in smart manufacturing.

What This Means for the Automotive Sector

The embrace of next-gen automated quality control systems signifies a profound shift in US automotive manufacturing. This isn’t merely an incremental upgrade; it represents a fundamental retooling of how vehicles are produced, inspected, and delivered. The verified 10% production boost underscores a new era of efficiency and precision, setting a precedent for global competitiveness. Stakeholders across the supply chain, from component suppliers to end consumers, will experience the ripple effects of enhanced reliability and consistent quality. This sustained commitment to technological advancement ensures the US automotive industry remains at the forefront of innovation, ready to meet future demands with unparalleled excellence.