2025 Automotive Technology: Boosting US Factory Efficiency

The 2025 automotive technology landscape is rapidly evolving, with key innovations driving unprecedented production efficiency in US factories, utilizing advanced robotics, AI, digital twins, and sustainable practices to transform manufacturing processes.

The automotive industry is on the cusp of a profound transformation, with game-changing innovations reshaping how vehicles are made. As of early 2024, the focus for US factories is squarely on enhancing efficiency and output. The 2025 Automotive Technology Landscape is defined by a convergence of advanced digital and physical solutions, promising a future where production lines are smarter, faster, and more sustainable. What are these key innovations, and how will they impact the American manufacturing sector?

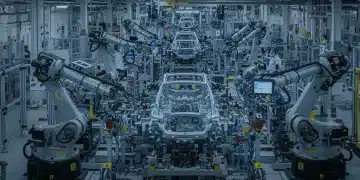

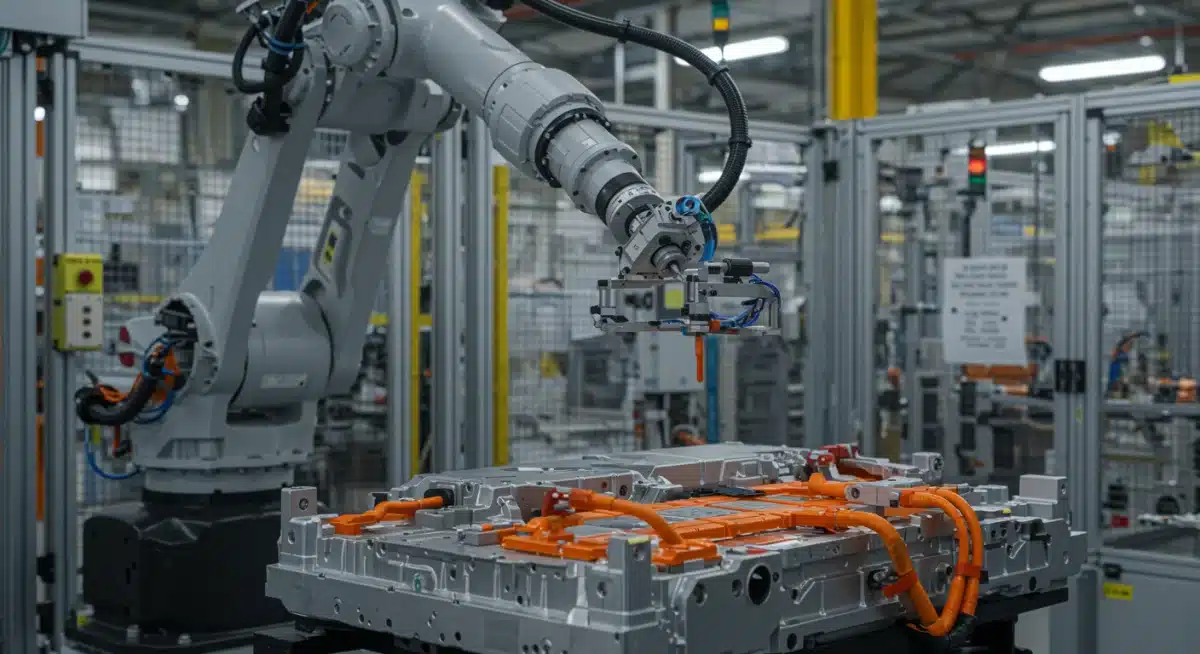

The Rise of Advanced Robotics and Automation

The integration of advanced robotics and automation continues to be a cornerstone of production efficiency in US automotive factories. These systems are evolving beyond traditional pick-and-place tasks, now demonstrating unprecedented levels of dexterity, cognitive ability, and collaborative potential. This shift is critical for handling complex assembly operations and improving worker safety.

Manufacturers are deploying next-generation collaborative robots (cobots) that work seamlessly alongside human operators, increasing throughput without requiring extensive safety caging. These cobots are equipped with sophisticated sensors and AI algorithms, allowing them to adapt to dynamic environments and perform precise tasks.

Cobots and Human-Robot Collaboration

Cobots are fundamentally changing the factory floor by offering flexibility and reducing the need for costly retooling. Their ability to learn and adjust means they can be deployed in various stages of production, from intricate component assembly to quality inspection.

- Enhanced Safety Features: Advanced sensors prevent collisions, ensuring a safe working environment for humans.

- Increased Flexibility: Easily reprogrammable for different tasks, reducing downtime and enhancing adaptability.

- Improved Ergonomics: Cobots handle repetitive or heavy lifting tasks, reducing strain and injury risks for human workers.

- Skill Augmentation: They can assist skilled workers, allowing them to focus on more complex, value-added activities.

Beyond cobots, fully autonomous mobile robots (AMRs) are streamlining logistics within factories, transporting parts and materials precisely where and when they are needed, further optimizing the supply chain within the plant itself. This reduces human intervention in material handling, freeing up personnel for more critical tasks.

Artificial Intelligence and Machine Learning in Production

Artificial Intelligence (AI) and Machine Learning (ML) are no longer futuristic concepts but essential tools driving efficiency in the 2025 Automotive Technology Landscape. These technologies are being embedded across the entire production lifecycle, from design and supply chain management to quality control and predictive maintenance.

AI algorithms analyze vast datasets generated by factory sensors, identifying patterns and anomalies that human operators might miss. This proactive approach allows for early detection of potential issues, preventing costly breakdowns and ensuring consistent quality.

Predictive Maintenance and Quality Control

One of the most significant applications of AI in automotive manufacturing is predictive maintenance. By continuously monitoring machinery performance and environmental factors, AI models can forecast equipment failures before they occur.

- Reduced Downtime: Maintenance can be scheduled precisely, minimizing unexpected production stoppages.

- Optimized Resource Allocation: Spare parts and maintenance crews can be dispatched efficiently.

- Extended Equipment Lifespan: Proactive care prevents minor issues from escalating into major damage.

In quality control, AI-powered vision systems are revolutionizing inspection processes. These systems can detect microscopic defects on components with unparalleled accuracy and speed, far surpassing human capabilities. This ensures that only the highest quality parts proceed to assembly, reducing rework and waste.

The Power of Digital Twins

Digital twins are rapidly becoming indispensable in the 2025 Automotive Technology Landscape, offering a virtual replica of physical assets, processes, and even entire factories. This dynamic digital model allows manufacturers to simulate, monitor, and optimize production in real-time, leading to significant gains in efficiency and problem-solving.

By creating a digital twin of a production line, engineers can test new configurations, processes, or equipment without disrupting actual operations. This virtual sandbox environment accelerates innovation and reduces risks associated with physical changes.

Simulation, Optimization, and Problem Solving

Digital twins provide a comprehensive view of factory operations, integrating data from various sources like sensors, ERP systems, and historical performance logs. This holistic perspective enables better decision-making and continuous improvement.

Through simulation, manufacturers can:

- Identify Bottlenecks: Pinpoint areas where production flow is impeded and develop solutions.

- Optimize Layouts: Experiment with different factory configurations to maximize space and efficiency.

- Test New Processes: Validate new manufacturing techniques or product designs virtually before physical implementation.

Moreover, digital twins facilitate remote monitoring and diagnostics. Experts can analyze factory performance from anywhere, providing immediate insights and support, which is particularly valuable for geographically dispersed operations or during unforeseen disruptions.

Additive Manufacturing (3D Printing) for Prototyping and Production

Additive Manufacturing, commonly known as 3D printing, is evolving beyond rapid prototyping to become a viable solution for producing end-use parts and tooling in the 2025 Automotive Technology Landscape. This technology offers unparalleled design freedom, material efficiency, and the ability to produce complex geometries that are impossible with traditional manufacturing methods.

US automotive factories are increasingly leveraging 3D printing for specialized components, jigs, fixtures, and even custom spare parts on demand. This reduces lead times, cuts down on tooling costs, and minimizes inventory requirements, contributing directly to production efficiency.

On-Demand Production and Customization

The ability to print parts on demand means manufacturers can respond quickly to design changes or market demands without significant retooling costs. This agility is a key advantage in a rapidly changing automotive market.

- Rapid Prototyping: Accelerates the design iteration process, bringing new vehicles to market faster.

- Custom Tooling: Creates custom jigs, fixtures, and molds quickly and affordably.

- Lightweight Components: Produces intricate, lightweight parts that improve vehicle performance and fuel efficiency.

- Supply Chain Resilience: Enables on-site production of critical parts, reducing reliance on external suppliers.

The use of advanced materials in 3D printing, such as high-strength polymers and metal alloys, is expanding its application range. This allows for the creation of components that meet stringent automotive performance and safety standards, further integrating additive manufacturing into core production processes.

Sustainable Manufacturing Practices and Circular Economy

Sustainability is no longer a peripheral concern but a central pillar of the 2025 Automotive Technology Landscape, driving innovations that boost efficiency while minimizing environmental impact. US factories are adopting circular economy principles, focusing on reducing waste, optimizing energy consumption, and incorporating recycled materials into their production processes.

This commitment to sustainable manufacturing not only addresses environmental responsibilities but also leads to significant operational efficiencies, including reduced material costs, lower energy bills, and improved brand reputation.

Resource Efficiency and Waste Reduction

Implementing sustainable practices involves a multi-faceted approach, encompassing everything from factory design to end-of-life product management. The goal is to create a closed-loop system where resources are continuously reused and recycled.

Key initiatives include:

- Energy Optimization: Deploying renewable energy sources, smart energy management systems, and energy-efficient machinery.

- Water Conservation: Implementing advanced water recycling and purification systems within facilities.

- Material Recycling: Increasing the use of recycled content in vehicle components and reducing scrap generation.

- Waste-to-Energy Programs: Converting manufacturing byproducts into usable energy.

Manufacturers are also exploring innovative materials that are lighter, more durable, and easier to recycle, contributing to both vehicle performance and environmental goals. The adoption of these practices is becoming a competitive differentiator, attracting environmentally conscious consumers and investors alike.

Data Analytics and IoT for Real-time Insights

The proliferation of sensors and interconnected devices, collectively known as the Internet of Things (IoT), is generating an unprecedented volume of data within automotive factories. In the 2025 Automotive Technology Landscape, advanced data analytics tools are crucial for transforming this raw data into actionable insights, driving real-time decision-making and continuous improvement in production efficiency.

IoT devices embedded in machinery, tools, and even products collect detailed information on performance, environmental conditions, and quality parameters. This data is then fed into powerful analytics platforms that identify trends, predict outcomes, and highlight areas for optimization.

Real-time Monitoring and Process Optimization

The ability to monitor production processes in real-time allows factory managers to respond instantly to deviations or inefficiencies, preventing minor issues from escalating into major problems. This immediate feedback loop is vital for maintaining high production standards and meeting tight schedules.

Data analytics facilitates:

- Performance Tracking: Continuous monitoring of machine uptime, throughput, and cycle times.

- Root Cause Analysis: Quickly identifying the underlying causes of production anomalies or defects.

- Process Refinement: Using data-driven insights to fine-tune manufacturing parameters for optimal results.

- Supply Chain Visibility: Gaining real-time insights into material flow and inventory levels to prevent disruptions.

Furthermore, machine learning algorithms can learn from historical data to continuously improve these analytical models, making them even more accurate and predictive over time. This creates a self-optimizing factory environment where efficiency gains are incremental and sustained, ensuring US automotive factories remain globally competitive.

| Key Innovation | Impact on Efficiency |

|---|---|

| Advanced Robotics | Boosts speed, precision, and safety in assembly, allowing human-robot collaboration for complex tasks. |

| AI & Machine Learning | Enables predictive maintenance, superior quality control, and data-driven process optimization. |

| Digital Twins | Offers virtual simulation for optimizing layouts, testing processes, and real-time monitoring without disruption. |

| Sustainable Manufacturing | Reduces waste, optimizes energy consumption, and lowers material costs through circular economy principles. |

Frequently Asked Questions About 2025 Automotive Production

The main drivers for efficiency in the 2025 automotive sector are advanced automation, artificial intelligence, digital twins, additive manufacturing, and sustainable practices. These technologies collectively aim to reduce waste, optimize production lines, enhance quality, and accelerate time to market for new vehicles.

Digital twins create virtual replicas of physical factories and processes. This allows manufacturers to simulate changes, test new layouts, and predict potential issues without halting real production. By identifying bottlenecks and optimizing workflows virtually, digital twins significantly reduce downtime and improve operational efficiency.

By 2025, AI plays a crucial role in predictive maintenance, quality control, and process optimization. AI algorithms analyze sensor data to forecast equipment failures, identify defects with high accuracy, and continuously refine manufacturing parameters, leading to fewer disruptions and higher product quality.

Yes, US automotive factories are increasingly adopting sustainable manufacturing practices. This includes optimizing energy and water consumption, increasing the use of recycled materials, and implementing waste-to-energy programs. These efforts not only benefit the environment but also drive operational efficiencies and reduce costs.

Additive manufacturing, or 3D printing, contributes to efficiency by enabling rapid prototyping, on-demand production of custom tooling and specialized parts, and reducing inventory needs. It offers design freedom for lightweight components and enhances supply chain resilience by allowing in-house part creation.

Looking Ahead

The rapid integration of these advanced technologies signals a transformative era for US automotive manufacturing. The continuous evolution of AI, robotics, digital twins, additive manufacturing, and sustainable practices is not merely about incremental improvements but a fundamental shift towards a more resilient, responsive, and efficient industry. Observers should anticipate further advancements in human-machine collaboration and greater emphasis on data security as these interconnected systems become more prevalent. The competitive landscape will increasingly favor companies that can swiftly adopt and integrate these innovations, ensuring the US remains at the forefront of automotive production.