Vehicle Lightweighting: 7% Fuel Economy Boost by 2025 in US Cars

New US cars are set to achieve a 7% improvement in fuel economy by 2025, largely driven by advancements in Vehicle Lightweighting Technologies, underscoring a critical industry push towards efficiency and sustainability.

Breaking news in the automotive sector reveals that significant strides in Vehicle Lightweighting Technologies are on track to enhance fuel economy by 7% in new US cars by 2025. This development marks a pivotal moment for both consumers and the environment, promising more efficient vehicles on American roads in the near future.

The Drive for Lighter Vehicles: Why it Matters Now

The push for lighter vehicles is intensifying, driven by stringent emissions regulations and consumer demand for greater fuel efficiency. Automakers are rapidly adopting innovative materials and manufacturing processes to shed vehicle weight without compromising safety or performance.

This strategic shift is not merely about compliance; it’s about redefining automotive engineering. The goal is to deliver cars that are not only more environmentally friendly but also offer enhanced driving dynamics and lower operating costs for consumers. As of late 2023, industry reports indicate a strong commitment to these lightweighting initiatives, with substantial investments in research and development.

Regulatory Pressures and Consumer Demands

Government mandates, particularly those related to Corporate Average Fuel Economy (CAFE) standards, are a primary catalyst. These regulations compel manufacturers to continuously improve the efficiency of their vehicle fleets. Simultaneously, consumers are increasingly prioritizing fuel-efficient options, influenced by fluctuating fuel prices and growing environmental awareness.

- Stricter emissions targets set by federal agencies.

- Rising global fuel prices influencing buyer decisions.

- Increased public awareness regarding carbon footprint.

- Demand for vehicles that offer both performance and efficiency.

Advanced Materials Revolutionizing Car Manufacturing

The core of Vehicle Lightweighting Technologies lies in the adoption of advanced materials. Traditional steel is being supplemented or replaced by lighter, stronger alternatives, fundamentally altering how cars are designed and constructed. This material revolution is critical to achieving the ambitious 2025 fuel economy targets.

Current trends show a significant uptick in the use of materials like high-strength steel, aluminum alloys, carbon fiber composites, and even advanced plastics. Each material offers unique properties that contribute to weight reduction while maintaining or improving structural integrity and crashworthiness. Manufacturers are meticulously balancing cost, performance, and sustainability in their material choices.

High-Strength Steel and Aluminum Alloys

High-strength steel (HSS) continues to be a workhorse, offering a balance of strength and weight reduction. Its advanced variants allow for thinner gauges without compromising safety. Aluminum alloys, however, are gaining significant traction due to their excellent strength-to-weight ratio. Many new vehicle platforms are now designed with extensive aluminum components, from body panels to engine blocks.

- High-Strength Steel: Allows for thinner components, maintaining safety.

- Aluminum Alloys: Significant weight savings, improving acceleration and braking.

- Magnesium Alloys: Even lighter than aluminum, used in select components.

Carbon Fiber and Composite Materials

Carbon fiber reinforced polymers (CFRPs) represent the pinnacle of lightweighting, offering exceptional strength and stiffness at a fraction of the weight of steel. While historically expensive, manufacturing costs are decreasing, making them more viable for mass-produced vehicles, especially in structural components and luxury segments. Other composite materials, including fiberglass and various polymer composites, are also finding applications in non-structural and semi-structural parts.

Innovative Manufacturing Processes for Weight Reduction

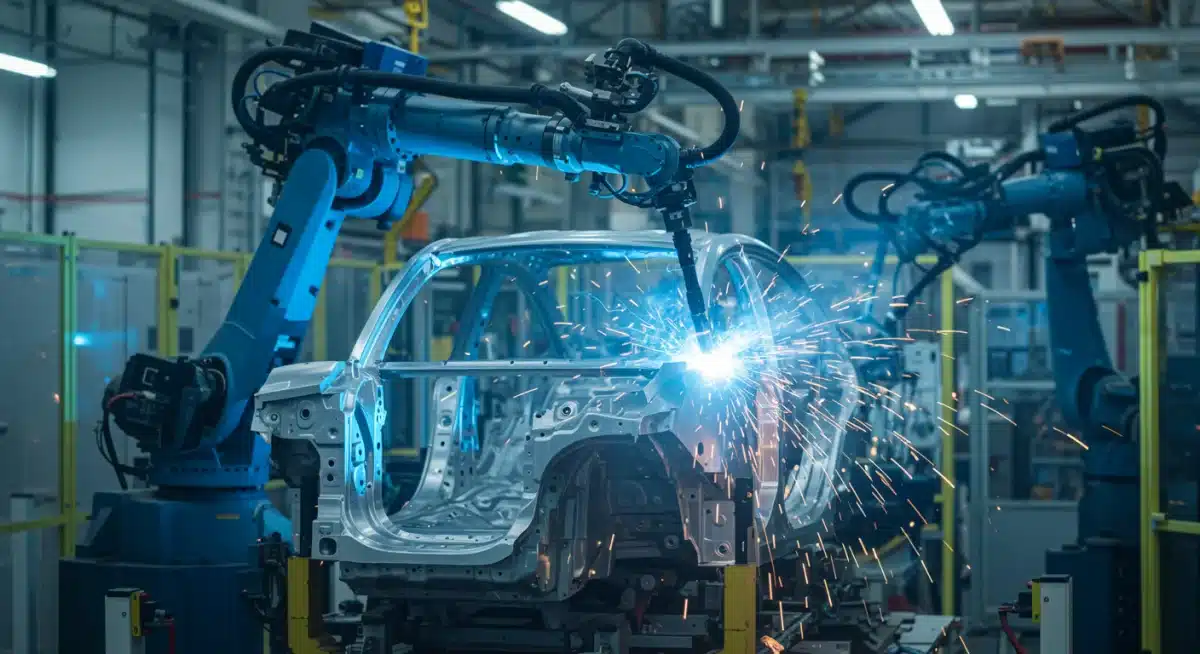

Beyond materials, innovative manufacturing processes are equally crucial for effective Vehicle Lightweighting Technologies. Automakers are investing heavily in advanced techniques that allow for the precise and efficient integration of lightweight materials, optimizing vehicle structure for minimal mass.

These processes include advanced joining techniques, such as laser welding and adhesive bonding, which reduce the need for heavier fasteners. Hydroforming, a method that uses high-pressure fluid to shape metal, allows for complex, lightweight component designs. Furthermore, additive manufacturing (3D printing) is being explored for producing intricate, optimized parts that are impossible to create with traditional methods, further pushing the boundaries of weight reduction.

Advanced Joining Techniques

Traditional welding can add weight and introduce stress points. New methods like friction stir welding for aluminum, laser welding for dissimilar materials, and structural adhesives are becoming standard. These techniques create stronger, lighter joints, enhancing overall vehicle integrity while reducing mass.

- Friction Stir Welding: Ideal for aluminum, creates strong, low-distortion joints.

- Laser Welding: Precision and speed, suitable for various material combinations.

- Structural Adhesives: Distribute stress evenly, improving stiffness and durability.

Optimized Design and Topology

Computational design tools, such as topology optimization, are playing a vital role. These tools allow engineers to design components that use the absolute minimum amount of material necessary to meet performance requirements. This results in parts with organic, often intricate shapes that are both lighter and stronger than conventionally designed counterparts.

Impact on Vehicle Performance and Safety

The benefits of Vehicle Lightweighting Technologies extend far beyond just fuel economy. Lighter vehicles exhibit improved performance characteristics and, counterintuitively to some, can also offer enhanced safety features. This holistic improvement makes lightweighting a win-win for manufacturers and consumers alike.

A lighter car requires less energy to accelerate, brake, and turn, leading to a more responsive and agile driving experience. This can translate into better handling and quicker acceleration. From a safety perspective, while a common misconception is that heavier cars are safer, modern engineering focuses on energy absorption and structural integrity. Lightweight designs, when engineered correctly with advanced materials, can manage crash energy more effectively, protecting occupants.

Enhanced Driving Dynamics

Reduced mass directly translates to improved power-to-weight ratios, allowing for better acceleration with smaller engines. It also significantly shortens braking distances and enhances cornering capabilities, contributing to a more engaging and safer driving experience. The agility gained from lightweighting transforms the feel of a vehicle.

Maintaining and Improving Safety Standards

Automakers are not sacrificing safety for weight savings. Instead, they are leveraging the superior strength of advanced materials like carbon fiber and high-strength steel to design crash structures that absorb impact energy more efficiently. This often results in safety ratings that are equal to, or even better than, those of heavier predecessors. Advanced computer simulations and extensive crash testing validate these lighter, safer designs.

Challenges and Future Outlook for Lightweighting

While the benefits of Vehicle Lightweighting Technologies are clear, the path to widespread adoption is not without its challenges. Cost, recyclability, and the need for new manufacturing infrastructure are significant hurdles that the automotive industry is actively addressing. However, the long-term outlook remains overwhelmingly positive, with continuous innovation driving progress.

The higher cost of advanced materials like carbon fiber and aluminum, compared to traditional steel, can impact vehicle pricing. Additionally, developing efficient and scalable recycling processes for mixed materials is crucial for environmental sustainability. Automakers are investing in new assembly lines and training for specialized manufacturing techniques required for these materials. Despite these challenges, the industry’s commitment to lightweighting remains strong, fueled by both regulatory pressures and the competitive advantage of offering more efficient vehicles.

Cost Implications and Recyclability

The upfront cost of advanced materials and the specialized processes needed to work with them can be higher. Manufacturers are working on economies of scale and new material formulations to bring these costs down. Recyclability is another key concern; developing methods to efficiently separate and reuse different lightweight materials is essential for a circular economy approach.

- High initial material and processing costs.

- Developing robust recycling infrastructure for mixed materials.

- Investment in new tooling and specialized labor.

The Road Ahead: Electrification and Autonomous Driving

Lightweighting is even more critical for electric vehicles (EVs), where reducing mass directly impacts battery range. For autonomous vehicles, lighter structures can improve sensor performance and overall system efficiency. The synergy between lightweighting and these emerging technologies will define the future of automotive design.

Achieving the 7% Fuel Economy Goal by 2025

The target of a 7% improvement in fuel economy for new US cars by 2025, largely attributed to Vehicle Lightweighting Technologies, is an ambitious yet achievable goal. This represents a significant leap forward in automotive efficiency, with profound implications for consumers, manufacturers, and environmental efforts. The collective efforts across material science, engineering, and manufacturing are converging to make this a reality.

This improvement will not come from a single breakthrough but from a combination of incremental gains across various lightweighting strategies. From optimized chassis designs and advanced propulsion systems to the pervasive use of lighter materials, every component is being scrutinized for weight reduction potential. The industry is demonstrating a clear commitment to meeting these targets, understanding that enhanced fuel economy is a cornerstone of future mobility.

Multi-faceted Approach to Efficiency

Achieving the 7% goal involves more than just material substitution. It encompasses a holistic approach including:

- Aerodynamic optimization for reduced drag.

- Development of more efficient powertrains.

- Integration of smart electronics to manage energy.

- Overall vehicle architecture designed for minimal mass.

Collaboration and Innovation

Success hinges on continued collaboration between automakers, material suppliers, and research institutions. Ongoing innovation in material science, additive manufacturing, and digital design tools will be key to overcoming remaining challenges and pushing the boundaries of what’s possible in vehicle lightweighting. The automotive landscape is rapidly evolving, with efficiency and sustainability at its core.

| Key Point | Brief Description |

|---|---|

| 7% Fuel Economy Goal | New US cars target a 7% fuel economy improvement by 2025, primarily through lightweighting efforts. |

| Advanced Materials | Increased use of high-strength steel, aluminum, and carbon fiber to reduce vehicle mass. |

| Innovative Processes | New manufacturing techniques like laser welding and topology optimization are key to integration. |

| Performance & Safety | Lightweighting enhances driving dynamics and maintains or improves crash safety through advanced design. |

Frequently Asked Questions About Vehicle Lightweighting

Vehicle Lightweighting Technologies involve reducing the overall weight of a car through advanced materials and optimized design. This includes using materials like high-strength steel, aluminum, and carbon fiber, as well as innovative manufacturing processes to achieve better fuel efficiency and performance.

Reducing vehicle weight directly lowers the energy needed for acceleration and overcoming rolling resistance. A 10% reduction in vehicle weight can lead to a 6-8% improvement in fuel economy, making the 7% target achievable by 2025 through comprehensive lightweighting strategies.

No, this is a common misconception. Modern lightweight designs utilize advanced, stronger materials and sophisticated engineering to absorb crash energy more effectively. This often results in safety ratings equal to, or superior to, heavier vehicles, as proven by rigorous crash testing.

Key materials include high-strength steel (HSS), various aluminum alloys, carbon fiber reinforced polymers (CFRPs), and magnesium alloys. These materials offer superior strength-to-weight ratios compared to traditional mild steel, enabling significant mass reduction across vehicle components.

Challenges include the higher cost of advanced materials, the need for new manufacturing processes and infrastructure, and developing efficient recycling methods for mixed materials. Overcoming these requires significant investment and ongoing innovation from the automotive industry.

What This Means

The ongoing advancements in Vehicle Lightweighting Technologies signal a transformative period for the US automotive market. Achieving a 7% fuel economy improvement by 2025 is not just a regulatory milestone; it represents a tangible benefit for consumers through reduced fuel costs and for the environment through lower emissions. This commitment to efficiency will undoubtedly shape future vehicle design, accelerating the transition towards a more sustainable and performance-driven automotive landscape. The industry’s proactive approach sets a clear precedent for innovation, impacting everything from consumer choices to global environmental policies.