Augmented Reality in Automotive Maintenance: Streamlining US Technician Training by 30% by 2025

Augmented Reality (AR) is poised to streamline US automotive technician training by 30% by 2025, introducing interactive and efficient learning methodologies across the industry.

The automotive industry is in constant evolution, and with it, the demands on its skilled workforce. A significant shift is currently underway as Augmented Reality in Automotive Maintenance: Streamlining US Technician Training by 30% by 2025 becomes a tangible goal, promising to revolutionize how technicians learn and perform complex tasks. This groundbreaking integration represents a pivotal moment for efficiency and expertise in vehicle servicing.

AR’s Immediate Impact on Training Protocols

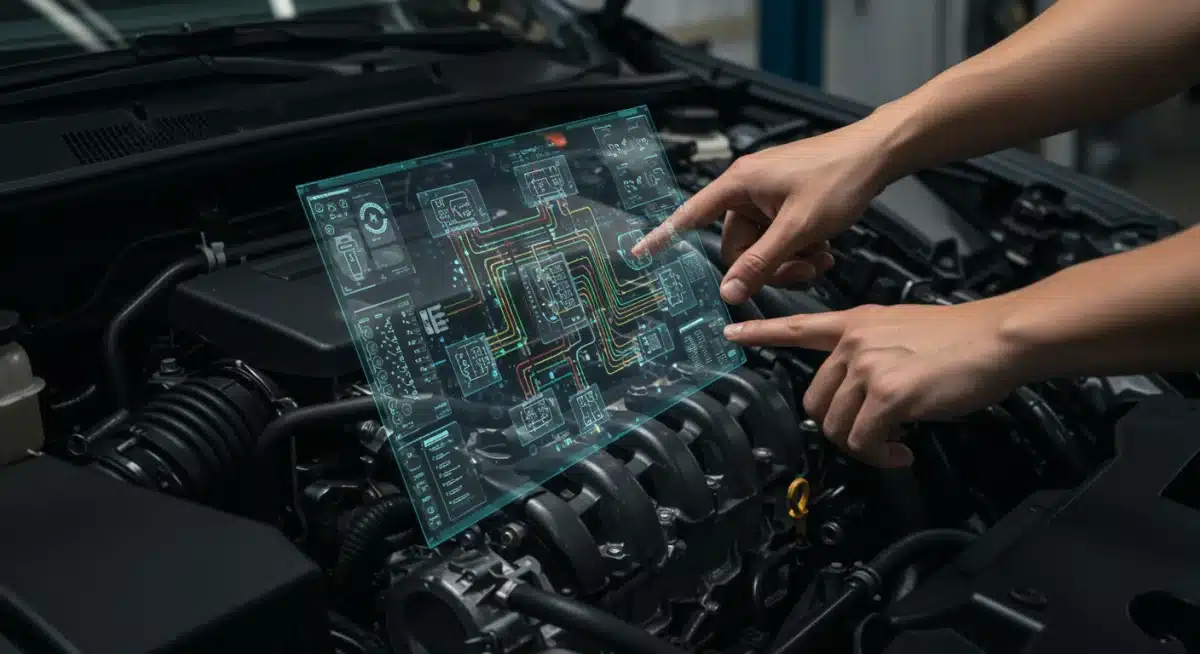

Augmented Reality is already demonstrating its immediate impact on automotive training protocols across the United States. This technology superimposes digital information onto the real world, providing technicians with interactive, hands-on learning experiences without the need for physical disassembly or extensive traditional classroom time. The shift is not just about novelty; it’s about practical, measurable improvements in learning retention and skill acquisition.

Leading automotive manufacturers and independent repair shops are investing heavily in AR solutions, recognizing the potential to bridge the skills gap and prepare their workforce for the increasingly complex vehicles of today and tomorrow. This includes electric vehicles, autonomous systems, and advanced driver-assistance systems (ADAS), which demand a new level of diagnostic and repair proficiency.

Enhanced Diagnostic Accuracy

One of the most compelling benefits of AR in automotive maintenance training is its ability to significantly enhance diagnostic accuracy. Trainees can view virtual schematics, component breakdowns, and real-time data overlays directly on the physical vehicle part they are examining. This visual guidance reduces guesswork and accelerates the learning curve for intricate diagnostic procedures.

- Real-time data visualization on components.

- Interactive step-by-step repair guides.

- 3D model overlays for complex assemblies.

- Remote expert assistance via AR collaboration tools.

The Drive Towards 30% Efficiency by 2025

The ambitious target of streamlining US technician training by 30% by 2025 through AR is driven by several key factors. The automotive sector faces a persistent shortage of skilled technicians, coupled with the rapid evolution of vehicle technology. AR offers a scalable and effective solution to address these challenges head-on, promising a future where training is faster, more engaging, and ultimately more effective. This efficiency gain isn’t merely about speed; it’s about producing more competent technicians in less time.

Industry leaders cite reduced training costs, minimized downtime for vehicles used in training, and improved overall technician readiness as primary motivators. The investment in AR technology is viewed as a strategic imperative to maintain competitiveness and service quality in a demanding market. Early adopters are already reporting significant improvements in their training metrics, providing a strong case for broader implementation.

Cost Reduction and Accessibility

AR training platforms significantly cut down on the costs associated with traditional training methods. There’s less need for multiple physical vehicles for practice, specialized tools for every trainee, or extensive travel for instructors. This makes high-quality training more accessible to a wider range of technicians, including those in remote areas.

Furthermore, the ability to repeat complex procedures virtually without consequence allows trainees to gain confidence and mastery before working on actual customer vehicles. This leads to fewer errors and higher quality repairs in the field, benefiting both service centers and vehicle owners.

Key Technologies Fueling AR Adoption

Several key technological advancements are fueling the widespread adoption of AR in automotive training. These include more affordable and powerful AR headsets, sophisticated software platforms designed for industrial applications, and improved connectivity that allows for real-time data streaming and remote collaboration. The convergence of these technologies creates a robust ecosystem for immersive learning.

Companies like Microsoft with HoloLens, Magic Leap, and various startups are developing purpose-built AR devices and software that cater specifically to the needs of the automotive maintenance sector. These tools are becoming more user-friendly and integrated into existing workshop environments, making the transition to AR-enhanced training smoother.

Software Innovations and 3D Modeling

The backbone of effective AR training lies in its software. Advanced 3D modeling tools allow for the creation of incredibly detailed virtual representations of vehicle components and systems. These models can be manipulated, dissected, and interacted with in ways that are impossible with physical objects, providing an unparalleled depth of understanding.

Artificial intelligence (AI) is also playing a crucial role, powering intelligent tutors within AR environments that can adapt to a trainee’s progress and provide personalized feedback. This adaptive learning approach ensures that each technician receives the most effective and tailored instruction, maximizing their learning potential.

Challenges and Solutions in Implementation

Despite the immense potential, the widespread implementation of AR in automotive maintenance training faces several challenges. These include the initial investment cost for hardware and software, the need for specialized content creation, and resistance to change from some traditionalists within the industry. Addressing these hurdles is critical for achieving the 2025 efficiency target.

To overcome these, many organizations are adopting phased implementation strategies, starting with pilot programs and gradually scaling up. Partnerships between AR technology providers and automotive training institutions are also becoming more common, facilitating the development of industry-specific content and best practices. Furthermore, demonstrating a clear return on investment (ROI) is key to securing broader buy-in.

Overcoming Data Security Concerns

As AR systems handle sensitive vehicle data and proprietary repair information, data security is a paramount concern. Developers are implementing robust encryption and access control measures to protect this information. Training programs also emphasize data privacy and responsible use of AR devices, ensuring compliance with industry standards and regulations.

- Phased rollout strategies for gradual adoption.

- Collaborations between tech firms and training centers.

- Focus on demonstrating clear ROI to stakeholders.

- Robust data encryption and privacy protocols.

The Future Landscape for US Automotive Technicians

The future landscape for US automotive technicians is undeniably shaped by Augmented Reality. As AR systems become more sophisticated and integrated, technicians will increasingly rely on these tools not just for training, but for day-to-day diagnostic and repair tasks. This will elevate the role of the technician, transforming them into highly skilled ‘tech-enabled’ professionals capable of handling the most advanced vehicles.

The continuous evolution of vehicle technology, particularly in areas like electric powertrains and autonomous driving, ensures that the demand for adaptable and highly trained technicians will only grow. AR provides the necessary framework to keep the workforce ahead of the curve, ensuring that service centers can meet consumer needs efficiently and effectively.

Moreover, AR is expected to foster a culture of continuous learning, allowing technicians to quickly update their skills as new vehicle models and technologies are introduced. This agile learning environment is crucial for maintaining expertise in a rapidly changing industry.

Success Stories and Early Adopters

Numerous success stories from early adopters are highlighting the transformative power of AR in automotive training. Major dealerships and service chains have reported significant reductions in training time and a notable improvement in first-time fix rates since integrating AR solutions. These tangible results serve as powerful testimonials for the broader industry.

For example, one leading automotive group implemented AR for high-voltage battery diagnostics on EVs, resulting in a 25% decrease in diagnostic time for new technicians and a 15% improvement in repair accuracy. Such outcomes validate the initial investments and encourage wider adoption, pushing the industry closer to the 30% efficiency target by 2025.

These early successes are not isolated incidents but rather a growing trend, demonstrating that AR is not just a futuristic concept but a practical, impactful tool that is already delivering significant value in the present.

| Key Aspect | Brief Description |

|---|---|

| Efficiency Target | Aiming for 30% streamlining of US automotive technician training by 2025 using AR. |

| AR Benefits | Enhances diagnostic accuracy, reduces training costs, and improves skill retention. |

| Key Technologies | Powered by advanced AR headsets, specialized software, and improved connectivity. |

| Challenges | Initial investment, content creation, and data security are primary hurdles. |

Frequently Asked Questions About AR in Automotive Training

Augmented Reality in automotive training involves overlaying digital information, such as 3D models, instructions, and data, onto a technician’s real-world view using devices like smart glasses or tablets. This creates an interactive, immersive learning environment for complex repairs and diagnostics.

AR streamlines training by providing real-time visual guidance, reducing the need for physical prototypes, cutting down travel for instructors, and accelerating skill acquisition. Its interactive nature improves learning retention and reduces errors, contributing to significant efficiency gains.

AR training is particularly beneficial for complex diagnostic procedures, high-voltage electric vehicle (EV) battery maintenance, advanced driver-assistance systems (ADAS) calibration, and intricate engine or transmission repairs, where visual overlays and step-by-step instructions are crucial.

Key challenges include the initial investment in AR hardware and software, the development of specialized training content, ensuring data security for proprietary information, and overcoming resistance to new technologies from some traditional training methodologies.

By providing precise, guided instructions and real-time feedback, AR significantly improves the accuracy of diagnostics and repairs. This leads to higher first-time fix rates, reduced rework, and ultimately, a higher quality of service for customers, enhancing overall industry standards.

Looking Ahead: The Evolving Role of Technicians

The swift integration of augmented reality into automotive maintenance training signifies a profound transformation for the US automotive workforce. As AR systems become integral, the role of the technician will evolve from traditional hands-on repair to a more technologically advanced, data-driven approach. This shift demands continuous upskilling and adaptability, with AR serving as a crucial tool for staying current.

Watch for further collaborations between tech companies and automotive giants, driving innovation in AR content and hardware. The success of achieving the 30% streamlining goal by 2025 will not only impact individual technicians but also reshape the entire service sector, setting new benchmarks for efficiency and expertise in vehicle care.