2025 EV Motor Technologies: Permanent Magnet vs. Induction Efficiency

The evolving landscape of electric vehicles is intensely focused on powertrain innovations, with a critical spotlight on the 2025 EV motor technologies. As manufacturers push for greater range and performance, understanding the fundamental differences and the efficiency gap between permanent magnet and induction motors becomes paramount. This comparison is not just academic; it directly impacts the future of EV design and consumer experience.

Understanding the Core Technologies

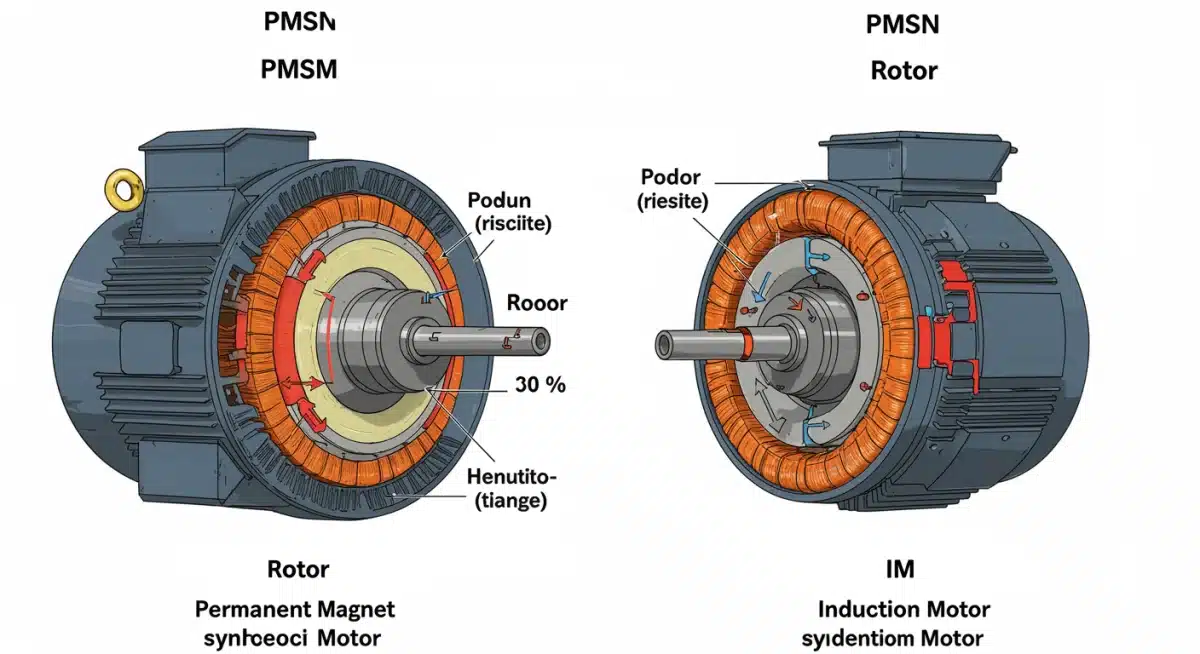

Electric vehicle propulsion relies heavily on the efficiency and characteristics of its electric motor. For 2025, the industry continues to primarily utilize two main types: Permanent Magnet Synchronous Motors (PMSMs) and Induction Motors (IMs). Each offers distinct advantages and disadvantages that influence vehicle performance, cost, and environmental footprint.

PMSMs, or permanent magnet motors, derive their name from the use of permanent magnets embedded in the rotor. These magnets create a constant magnetic field, allowing for highly efficient power conversion, especially at lower speeds and under light load conditions. This inherent magnetic field reduces the need for external excitation current in the rotor, contributing to their high efficiency.

Permanent Magnet Synchronous Motors (PMSMs)

- High Efficiency: PMSMs typically boast higher efficiency, particularly in urban driving cycles where frequent stops and starts occur. This is largely due to the fixed magnetic field provided by the permanent magnets.

- Power Density: They offer excellent power and torque density for their size, making them ideal for compact EV designs where space and weight are critical considerations.

- Cost Implications: The reliance on rare-earth materials, such as Neodymium, for their magnets can lead to higher material costs and supply chain vulnerabilities, a significant factor for 2025 production targets.

- Thermal Management: Higher power density can sometimes lead to more challenging thermal management requirements, as heat dissipation becomes crucial for sustained performance.

The Rise of Induction Motors in EVs

Induction motors, on the other hand, operate on the principle of electromagnetic induction to produce torque. Unlike PMSMs, their rotors do not contain permanent magnets. Instead, they feature conductive bars that form a squirrel cage, and current is induced in these bars by the stator’s rotating magnetic field, creating the necessary magnetic poles.

Historically, induction motors have been favored for their robustness, lower cost, and ability to operate without rare-earth materials. While they might exhibit slightly lower peak efficiency compared to PMSMs, continuous advancements in power electronics and control systems are closing this gap, making them increasingly competitive for various EV applications.

Key Characteristics of Induction Motors (IMs)

- Robustness and Cost-Effectiveness: IMs are generally simpler in construction and do not require rare-earth magnets, leading to lower manufacturing costs and greater supply chain stability.

- Variable Efficiency: Their efficiency can vary more significantly across the operating range, often performing optimally at higher speeds and loads. At light loads, they can be less efficient than PMSMs due to excitation losses.

- Thermal Performance: They tend to be more forgiving with thermal management due to their construction and often larger size for comparable power output.

- Regenerative Braking: IMs are highly effective in regenerative braking scenarios, efficiently converting kinetic energy back into electrical energy to recharge the battery.

Analyzing the 10% Efficiency Gap

The often-cited 10% efficiency gap between permanent magnet and induction motors is a critical point of discussion for 2025 EV motor technologies. This figure represents an average difference in peak efficiency under specific operating conditions, particularly noticeable in city driving or mixed cycles where PMSMs tend to shine. However, this gap is not static and is subject to continuous technological improvements.

For instance, while a PMSM might achieve 95-97% efficiency at its optimal point, an induction motor might be in the 88-92% range under similar conditions. This seemingly small percentage can translate into significant differences in vehicle range, battery size requirements, and overall energy consumption over the lifetime of an EV. The real-world impact depends heavily on the driving cycle and the specific motor design and control strategies employed by the manufacturer.

Manufacturers are actively working to mitigate this gap through advanced materials, improved winding techniques, and sophisticated control algorithms. The goal is to maximize efficiency across the entire operating range, not just at peak performance, to deliver optimal results for consumers.

Strategic Choices by EV Manufacturers

The decision between permanent magnet and induction motors for 2025 EV models is a strategic one for manufacturers, balancing performance, cost, and sustainability. Companies like Tesla have famously used both types, often pairing them in dual-motor configurations to leverage the strengths of each. For example, a PMSM might handle front-axle duties for efficiency, while an IM provides robust power for the rear, or vice versa.

The rising cost and geopolitical concerns surrounding rare-earth materials have prompted some manufacturers to explore rare-earth-free PMSM designs or to invest further in optimizing induction motor performance. This push towards diversification reduces reliance on volatile supply chains and contributes to more sustainable manufacturing practices.

Manufacturer Strategies for 2025

- Hybrid Motor Setups: Many high-performance EVs utilize a combination of PMSM and IM to achieve a balance of efficiency and raw power, optimizing for different driving conditions.

- Rare-Earth Reduction: Significant R&D is focused on reducing or eliminating rare-earth elements in PMSMs, using alternative magnet materials or innovative motor architectures.

- Advanced Control Systems: Sophisticated software and power electronics are enhancing the efficiency of both motor types, allowing for more precise control over torque and power delivery.

- Cost-Benefit Analysis: The choice often comes down to the target market segment and the desired balance between initial cost, long-term operational efficiency, and environmental impact.

Innovations Bridging the Efficiency Divide

The landscape of 2025 EV motor technologies is characterized by continuous innovation aimed at bridging the performance and efficiency divide between PMSMs and IMs. This includes advancements in materials science, manufacturing processes, and power electronics. New magnetic materials are being developed that offer PMSM-like performance without relying heavily on traditional rare earths.

For induction motors, improvements in rotor design, such as copper cage rotors, and more efficient cooling systems are significantly boosting their efficiency and power density. Furthermore, the integration of advanced silicon carbide (SiC) inverters is allowing both motor types to operate at higher frequencies and temperatures, leading to further efficiency gains and reduced losses in the power conversion process.

Key Innovations Impacting Motor Efficiency

- New Magnetic Materials: Research into ferrite magnets and other rare-earth-free alternatives for PMSMs aims to maintain performance while reducing material costs and supply chain risks.

- Silicon Carbide (SiC) Inverters: These advanced power electronics significantly reduce switching losses, allowing motors to operate at higher frequencies and temperatures with greater efficiency, boosting overall powertrain performance and extending EV range.

- Improved Cooling Systems: Enhanced thermal management is crucial for higher power density motors, preventing efficiency drops due to overheating and extending component life.

- Additive Manufacturing: 3D printing techniques are being explored for complex motor components, potentially enabling lighter, more efficient designs with optimized magnetic paths.

Future Outlook for EV Motor Technologies

Looking ahead to 2025 and beyond, the evolution of EV motor technologies will continue to be driven by the twin goals of maximizing efficiency and minimizing environmental impact and cost. While the 10% efficiency gap between permanent magnet and induction motors remains a benchmark, it is increasingly being narrowed by ongoing research and development. The industry is moving towards a more diversified approach, where the optimal motor choice is dictated by the specific application, vehicle segment, and regional supply chain considerations.

Expect to see a continued emphasis on sustainable materials, further integration of artificial intelligence in motor control for real-time optimization, and potentially new motor architectures that combine the best attributes of current technologies. The drive for higher performance, longer range, and more affordable electric vehicles will ensure that motor technology remains a vibrant and rapidly evolving field.

The dynamic interplay between technological advancements, market demands, and geopolitical factors will ultimately shape the motor landscape for the next generation of electric vehicles. The competition between PMSMs and IMs will likely transform into a collaboration, with manufacturers strategically deploying the best available technology for each unique application within their diverse EV portfolios.

| Key Aspect | Brief Description |

|---|---|

| Efficiency Gap | PMSMs generally 5-10% more efficient than IMs, especially at low speeds, impacting EV range. |

| PMSM Advantages | Higher power density, better low-speed efficiency, crucial for urban driving cycles. |

| IM Advantages | More robust, lower material cost, no rare-earth reliance, good high-speed performance. |

| Future Trends | Focus on rare-earth-free designs, SiC inverters, and hybrid motor configurations to optimize performance. |

Frequently Asked Questions About EV Motor Technologies

Permanent magnet motors (PMSMs) use rare-earth magnets in their rotors to create a constant magnetic field, offering high efficiency and power density. Induction motors (IMs) induce a magnetic field in their rotors via electromagnetic induction, making them more robust and cost-effective without needing rare earths.

The efficiency gap, often around 10%, stems from PMSMs’ inherent magnetic field, which reduces excitation losses, especially at lower speeds. IMs require current to induce their magnetic field, leading to some energy loss, particularly at light loads, although modern designs are minimizing this.

Manufacturers are addressing this by exploring rare-earth-free PMSM designs, optimizing induction motor performance, and utilizing hybrid motor configurations that combine both types. This strategy diversifies material reliance and balances cost with performance for 2025 EV motor technologies.

SiC inverters significantly reduce power losses during the conversion of DC battery power to AC motor power. This allows motors to operate at higher frequencies and temperatures with greater efficiency, boosting overall powertrain performance and extending EV range.

It is unlikely one type will completely replace the other. The trend for 2025 EV motor technologies suggests a continued strategic deployment of both. Manufacturers will choose based on specific vehicle requirements, cost targets, and supply chain stability, often combining them for optimal performance.

Looking Ahead

The ongoing evolution of 2025 EV motor technologies signifies a dynamic period for the automotive industry. The efficiency gap between permanent magnet and induction motors, while a key performance metric, is continuously being refined through innovation. As we move forward, expect to see further advancements in material science, power electronics, and integrated design that will blur the lines between these two motor types, leading to even more efficient, powerful, and sustainable electric vehicles on our roads. The strategic decisions made by manufacturers in the coming months will profoundly shape the next generation of EV performance and accessibility.

The dynamic interplay between technological advancements, market demands, and geopolitical factors will ultimately shape the motor landscape for the next generation of electric vehicles. The competition between PMSMs and IMs will likely transform into a collaboration, with manufacturers strategically deploying the best available technology for each unique application within their diverse EV portfolios.