Automotive Industry Chip Shortage: Production Cuts Through 2025

The automotive industry continues to grapple with a severe chip shortage, leading to significant production cuts expected to persist through 2025, impacting vehicle availability and prices globally.

The global automotive industry is currently navigating a turbulent period marked by a persistent and disruptive challenge: a critical **automotive industry faces chip shortage: production cuts expected to last through 2025**. This shortage, impacting everything from vehicle production to consumer choice, shows no signs of abating soon.

With analysts predicting that **automotive industry faces chip shortage: production cuts expected to last through 2025**, what are the key factors exacerbating the situation, and what strategies can automakers and consumers employ to mitigate the impact of **automotive industry faces chip shortage: production cuts expected to last through 2025**?

Understanding the Global Chip Shortage Impacting Automotive Production

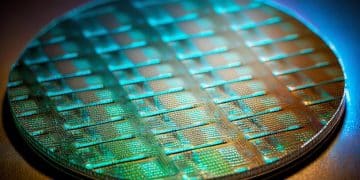

The automotive industry relies heavily on semiconductor chips for various functions, from engine management and safety systems to infotainment and driver-assistance features. The current global chip shortage has significantly disrupted automotive production, leading to plant shutdowns, reduced output, and longer delivery times for consumers.

Factors Contributing to the Chip Shortage

Several factors have converged to create this unprecedented shortage. The COVID-19 pandemic led to a surge in demand for consumer electronics, as people worked and learned from home. This increased demand strained the capacity of chip manufacturers, diverting resources away from the automotive sector. Additionally, geopolitical tensions, natural disasters, and logistical bottlenecks have further compounded the problem.

The Ripple Effect Across the Automotive Supply Chain

The shortage of chips has a cascading effect across the automotive supply chain. Tier 1 suppliers, who provide components and systems to automakers, are struggling to secure enough chips to meet their production schedules. This, in turn, forces automakers to reduce their output, impacting dealerships, and ultimately, consumers.

- Reduced Vehicle Availability: Production cuts lead to fewer vehicles being produced, resulting in limited inventory at dealerships.

- Longer Wait Times: Consumers face extended waiting periods for new vehicles, as automakers struggle to catch up with demand.

- Increased Vehicle Prices: Limited supply and high demand have driven up vehicle prices, making it more expensive for consumers to purchase new cars.

The **automotive industry faces chip shortage: production cuts expected to last through 2025** is a major problem. The shortage is not just a temporary inconvenience; it is a structural issue that will likely persist for several years.

Analyzing Production Cuts and Their Consequences

The ongoing chip shortage has forced automakers to implement significant production cuts across their global operations. These cuts have had far-reaching consequences, impacting not only the automotive industry but also the broader economy.

Extent of Production Cuts Across Major Automakers

Major automakers, including Ford, General Motors, Toyota, and Volkswagen, have all announced substantial production cuts due to the chip shortage. Some plants have been temporarily shut down, while others are operating at reduced capacity. The extent of the cuts varies depending on the automaker and the region, but the overall trend is clear: the chip shortage is severely curtailing automotive production.

Impact on Dealerships and Consumers

Production cuts have a direct impact on dealerships and consumers. With fewer vehicles available, dealerships are struggling to meet demand, leading to longer wait times and increased prices. Consumers who need a new car may have to settle for a less desirable model or delay their purchase altogether.

Economic Repercussions of Reduced Automotive Output

The automotive industry is a major contributor to the global economy, and any significant disruption in production can have serious economic consequences. Reduced automotive output can lead to job losses, lower tax revenues, and slower economic growth. The **automotive industry faces chip shortage: production cuts expected to last through 2025** has the power to impact the economy.

- Job Losses: Automakers and suppliers may be forced to lay off workers due to reduced production.

- Lower Tax Revenues: Reduced automotive sales can lead to lower tax revenues for governments.

- Slower Economic Growth: The automotive industry is a key driver of economic growth, and any slowdown in production can hamper overall economic activity.

The automotive industry is taking steps to address the chip shortage. However, it may take some time to resolve the issue. In the meantime, dealerships and consumers need to be patient and flexible.

Forecasting the Chip Shortage: Projections Through 2025

Industry analysts and experts are closely monitoring the chip shortage to forecast its duration and potential impact. While there is some disagreement on the exact timeline, most projections indicate that the shortage will persist through 2025, with some suggesting it could even extend beyond that.

Factors Influencing the Duration of the Shortage

Several factors will influence the duration of the chip shortage. These include the pace of capacity expansion by chip manufacturers, the evolution of demand for consumer electronics, and the resolution of geopolitical tensions. The faster chip manufacturers can increase their production capacity, the sooner the shortage will ease. However, building new chip fabs is a complex and time-consuming process, so it will likely take several years to significantly increase chip supply.

Expert Opinions and Industry Predictions

Leading industry analysts and experts have offered various predictions regarding the chip shortage. Some believe that the shortage will begin to ease in the second half of 2024, while others anticipate it will last through 2025 or even beyond. The consensus is that the shortage will remain a significant challenge for the automotive industry for at least the next year.

Long-Term Implications for the Automotive Industry

The chip shortage has several long-term implications for the automotive industry. It has highlighted the industry’s dependence on a complex and vulnerable global supply chain. It has also accelerated the adoption of new technologies, such as electric vehicles and autonomous driving systems, which require even more chips. Furthermore, the shortage has forced automakers to rethink their manufacturing strategies and invest in greater supply chain resilience.

The **automotive industry faces chip shortage: production cuts expected to last through 2025**, with many analysts predicting a slow and gradual recovery. The duration is based on capital expenditures.

Strategies for Automakers to Mitigate the Chip Shortage

Faced with the ongoing chip shortage, automakers are implementing various strategies to mitigate its impact. These strategies aim to secure a more reliable supply of chips, optimize production processes, and enhance supply chain resilience.

Diversifying Chip Suppliers and Building Strategic Partnerships

One key strategy is to diversify chip suppliers and build strategic partnerships with chip manufacturers. By reducing reliance on a single supplier, automakers can reduce their vulnerability to disruptions. Furthermore, collaborating with chip manufacturers on research and development can help ensure a more stable and predictable supply of chips in the long term.

Optimizing Vehicle Configurations and Focusing on High-Demand Models

Another strategy is to optimize vehicle configurations and focus on high-demand models. By simplifying vehicle designs and reducing the number of chip-intensive features, automakers can reduce their overall chip requirements. Focusing on high-demand models can help maximize revenue and profitability during a period of constrained supply.

Investing in Supply Chain Resilience and Inventory Management

Investing in supply chain resilience and inventory management is also crucial. This includes building buffer stocks of critical chips, diversifying sourcing locations, and implementing advanced supply chain planning tools. By improving their ability to anticipate and respond to disruptions, automakers can minimize the impact of future chip shortages.

- Negotiate long-term contracts with chip suppliers to secure a more stable supply.

- Invest in in-house chip design capabilities to reduce reliance on external suppliers.

- Explore alternative chip technologies and materials to reduce dependence on scarce resources.

These steps are meant to prevent the **automotive industry faces chip shortage: production cuts expected to last through 2025** from worsening. Automakers are working diligently to minimize the impact.

Impact on Consumers and Potential Solutions

The chip shortage has a direct impact on consumers, leading to longer wait times, higher prices, and limited vehicle choices. However, there are also potential solutions that consumers can explore to mitigate the impact of the shortage.

Extended Wait Times and Rising Vehicle Prices

As mentioned earlier, consumers are facing extended wait times and rising vehicle prices due to the chip shortage. Dealerships have limited inventory, and demand for new cars remains high, driving up prices. Consumers who need a new car may have to wait several months or even longer to receive their vehicle.

Exploring Used Car Options and Leasing Alternatives

One potential solution is to explore used car options or leasing alternatives. The used car market has seen a surge in demand as consumers seek to avoid the long wait times and high prices associated with new cars. Leasing can also be an attractive option, as it allows consumers to drive a new car without committing to a long-term purchase.

Being Flexible with Vehicle Features and Options

Another solution is to be flexible with vehicle features and options. Consumers who are willing to forego certain features or options that require scarce chips may be able to get a new car sooner. For example, some automakers are offering vehicles without certain advanced driver-assistance features to reduce chip requirements.

| Key Point | Brief Description |

|---|---|

| 🏭 Production Cuts | Automakers are reducing output due to chip scarcity. |

| ⏳ Shortage Duration | Expected to last through 2025, impacting availability. |

| 💰 Price Increases | Vehicle prices are rising amidst limited supply and high demand. |

| 🤝 Mitigation Strategies | Diversifying suppliers and optimizing configurations help alleviate chip scarcity. |

Frequently Asked Questions

The automotive industry is facing a crunch because the COVID-19 pandemic created a surge in demand for consumer electronics and subsequent production capacity strains.

Industry analysts predict the chip shortage could continue through 2025, with possible long-term effects based on the global situation and chip manufacturing capacities.

Consumers face longer wait times for new vehicles and may encounter increased prices due to limited supply caused by production cuts in the automotive industry.

Automakers are diversifying their chip suppliers, optimizing vehicle configurations, and investing in long-term supply chain resilience to mitigate the impact of chip shortages.

Yes, electric vehicles require even more chips than traditional vehicles, so the chip shortage can potentially slow down the production and availability of electric models.

Conclusion

The automotive industry is grappling with a significant **automotive industry faces chip shortage: production cuts expected to last through 2025**, leading to production cuts and various challenges. As automakers adapt and implement mitigation strategies, the industry is expected to address the supply chain issues.

Consumers can stay informed and be flexible in their purchasing decisions during this time. The global chip shortage poses challenges for consumers, but by staying informed and keeping up with strategies implemented, people can be prepared.