EV Battery Breakthroughs 2025: US Developments

By 2025, the US electric vehicle market anticipates significant advancements in battery technology, with solid-state, silicon anode, and lithium-sulfur batteries emerging as the most promising developments for enhanced range, faster charging, and improved safety.

The landscape of electric vehicles (EVs) is on the cusp of a transformative leap, driven by groundbreaking innovations in battery technology. As of late 2024, the United States is at the forefront of these developments, with key players racing to commercialize solutions that promise to redefine EV performance. This report delves into the most promising Battery Technology Breakthroughs for EVs: Analyzing the 3 Most Promising Developments for 2025 in the US, poised to deliver longer ranges, quicker charging times, and enhanced safety for the next generation of electric vehicles.

The Rise of Solid-State Batteries: A Game Changer for EVs

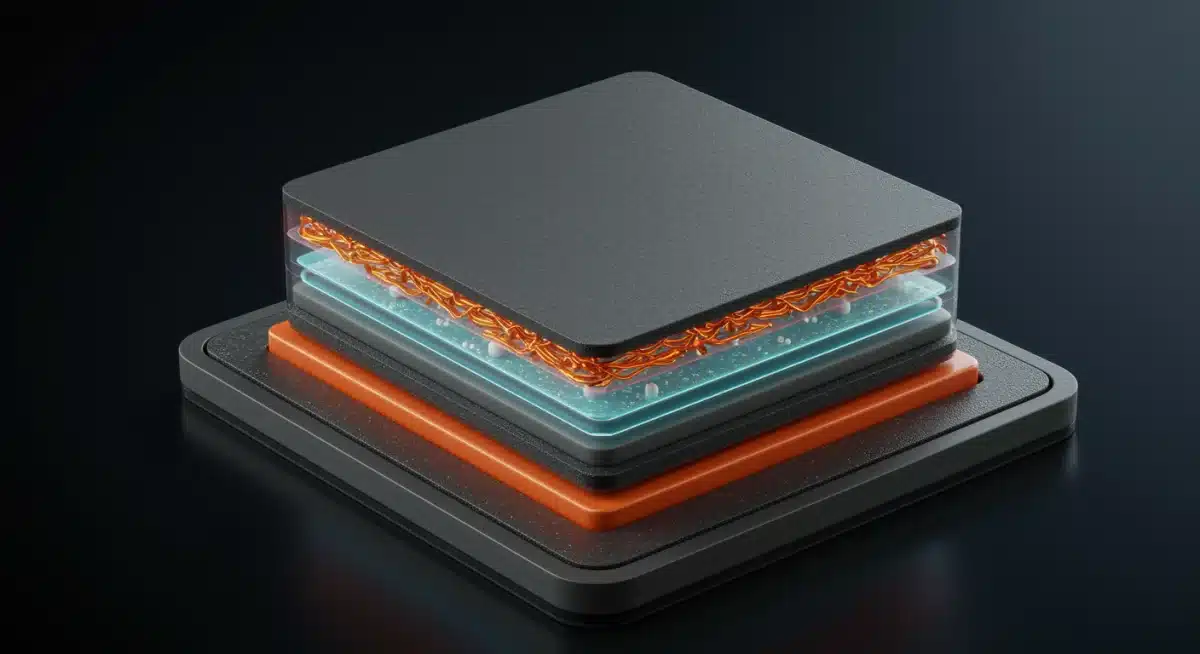

Solid-state batteries are widely considered the holy grail of EV power sources, promising a fundamental shift from current lithium-ion technology. These batteries replace the liquid or gel electrolyte found in traditional batteries with a solid material, offering significant advantages in energy density, safety, and cycle life. Several US-based companies and research institutions are making rapid strides, with 2025 marked as a critical year for potential pilot production and integration into high-end EV models.

The shift to a solid electrolyte eliminates the risk of flammability associated with liquid electrolytes, a major safety concern for current EV batteries. This inherent safety allows for more compact battery designs and higher energy packing, directly translating to longer driving ranges for electric vehicles. Furthermore, solid-state batteries are expected to handle faster charging rates without degradation, addressing another key consumer concern.

Key Advantages of Solid-State Technology

- Enhanced Safety: Eliminates flammable liquid electrolytes, reducing fire risk significantly.

- Higher Energy Density: Allows for more energy storage in a smaller, lighter package, increasing EV range.

- Faster Charging: Expected to support ultra-rapid charging without compromising battery lifespan.

- Longer Lifespan: Improved cycle stability leads to a longer operational life for the battery pack.

QuantumScape, a prominent US solid-state battery developer, has been a focal point of recent news, demonstrating impressive performance metrics in prototype cells. Their technology, backed by Volkswagen, aims to achieve 80% charge in just 15 minutes and significantly extend vehicle range. While mass production challenges remain, the progress indicates a tangible path toward commercial viability by the mid-decade.

Silicon Anode Batteries: Boosting Energy Density Now

While solid-state batteries represent a long-term vision, silicon anode technology offers a more immediate pathway to improved EV performance. Current lithium-ion batteries predominantly use graphite anodes, which have reached their theoretical energy density limits. Silicon, however, can store significantly more lithium ions, theoretically increasing battery energy density by up to ten times compared to graphite.

The primary challenge with silicon anodes has been their tendency to expand and contract dramatically during charging and discharging cycles, leading to mechanical stress and rapid degradation. However, recent breakthroughs in material science, particularly in nano-structured silicon and composite materials, are overcoming these hurdles. Companies like Sila Nanotechnologies and Group14 Technologies are leading the charge in developing stable and scalable silicon anode solutions.

By integrating even a small percentage of silicon into graphite anodes, EV manufacturers can see a noticeable increase in range without redesigning the entire battery architecture. This makes silicon anode technology a highly attractive option for implementation in the near term, potentially reaching mainstream EVs by 2025. The impact on existing battery production lines could be less disruptive than a full transition to solid-state.

Innovations in Silicon Anode Design

- Nano-structured Silicon: Reduces volume expansion issues, enhancing stability and cycle life.

- Silicon-Graphite Composites: Blends the benefits of both materials, offering incremental but significant improvements.

- Advanced Binders and Electrolytes: New formulations help manage silicon’s expansion and improve overall performance.

These advancements are not just theoretical; several battery cell manufacturers are already incorporating silicon-enhanced anodes into their products. The gradual integration of silicon is expected to provide a crucial bridge, pushing the boundaries of EV range and performance while solid-state technologies continue their path to full commercialization.

Lithium-Sulfur Batteries: The Promise of Ultra-High Energy

Lithium-sulfur (Li-S) batteries are another compelling technology garnering significant attention for their potential to deliver exceptionally high energy densities, far surpassing even advanced lithium-ion chemistries. Sulfur is abundant and inexpensive, making Li-S batteries a potentially cost-effective solution for future EVs. The theoretical energy density of Li-S batteries is nearly five times that of conventional lithium-ion batteries, promising EVs with ranges exceeding 1000 miles on a single charge.

Despite their immense promise, Li-S batteries face their own set of challenges, primarily related to the ‘polysulfide shuttle effect’ and the low conductivity of sulfur. The polysulfide shuttle leads to rapid capacity fade and poor cycle life, making commercialization difficult. However, ongoing research in the US, particularly at universities and startups like Sion Power, is developing novel electrolytes and cathode structures to mitigate these issues.

Recent developments include the use of advanced carbon hosts and protective layers to encapsulate sulfur, preventing the formation of soluble polysulfides. These innovations are significantly improving the cycle stability and overall efficiency of Li-S cells. While perhaps a bit further out than silicon anodes for widespread adoption, 2025 could see crucial pilot projects and demonstrations validating their long-term potential for specific high-performance or heavy-duty EV applications.

Overcoming Li-S Battery Challenges

- Polysulfide Shuttle Mitigation: Advanced electrolytes and separators prevent active material loss.

- Improved Sulfur Utilization: Novel cathode designs enhance the electrochemical activity of sulfur.

- Enhanced Cycle Life: Addressing degradation mechanisms to ensure long-term battery performance.

The environmental benefit of using sulfur, a widely available and non-toxic element, also adds to the appeal of Li-S technology. As the world pushes for more sustainable sourcing of battery materials, Li-S batteries could offer a significant advantage over other chemistries reliant on more scarce or controversial elements. This combination of high energy and sustainability makes Li-S a strong contender for the future of EV power.

Infrastructure and Regulatory Landscape for New Battery Technologies

The successful integration of these new battery technologies into the US automotive market hinges not just on their technical prowess, but also on the developing infrastructure and regulatory framework. The Biden administration’s push for EV adoption, coupled with investments in charging infrastructure and battery manufacturing, creates a fertile ground for these innovations. Policies like the Inflation Reduction Act (IRA) are incentivizing domestic battery production and supply chain development, which is crucial for scaling up new chemistries.

As these technologies mature, regulatory bodies will need to establish new safety standards and testing protocols tailored to their unique characteristics. For instance, solid-state batteries, inherently safer, might allow for different packaging and integration methods. The rapid pace of innovation necessitates a flexible yet robust regulatory environment that can adapt without stifling progress. This adaptive approach is vital for ensuring that breakthroughs translate into tangible benefits for consumers and the environment.

Furthermore, the recycling infrastructure for these new battery types will need to evolve. While lithium-ion recycling is gaining traction, solid-state and lithium-sulfur batteries present different material compositions and recovery challenges. Planning for end-of-life solutions from the outset is critical for the long-term sustainability of these advanced battery technologies and for maximizing their environmental benefits. Industry consortia and government-funded research are already exploring these future recycling pathways.

Economic Impact and Market Adoption in the US

The commercialization of these advanced battery technologies promises a significant economic impact across the US. Domestic manufacturing of these next-generation cells will create thousands of high-skilled jobs, from research and development to production and recycling. This aligns with national goals of strengthening supply chains and reducing reliance on foreign battery imports, enhancing national economic security.

For consumers, these breakthroughs mean more affordable, higher-performing electric vehicles. Longer ranges will alleviate range anxiety, faster charging will make EVs more convenient for long-distance travel, and improved safety will boost consumer confidence. The competitive landscape among EV manufacturers will intensify, driving down costs and accelerating the adoption of electric vehicles across all segments of the market. This competitive pressure will also spur further innovation, creating a positive feedback loop.

Investment in these technologies is robust, with venture capital firms, established automotive giants, and government grants pouring funds into promising startups and research initiatives. This financial backing underscores the high confidence in the potential of solid-state, silicon anode, and lithium-sulfur batteries to capture a substantial share of the future energy storage market. The US is positioning itself not just as a consumer, but as a global leader in the next era of battery innovation.

Challenges and the Path to Mass Production by 2025 and Beyond

While the promise is undeniable, the path to mass production for solid-state, silicon anode, and lithium-sulfur batteries is not without significant challenges. Scaling up novel manufacturing processes from laboratory prototypes to gigafactory-level production requires immense capital investment and meticulous engineering. Ensuring consistent quality, reliability, and cost-effectiveness at scale are paramount hurdles that must be overcome for widespread adoption by 2025 and beyond.

Each technology faces unique manufacturing complexities. Solid-state batteries require extremely precise assembly in controlled environments to prevent defects in the solid electrolyte. Silicon anode production needs to manage the material’s expansion properties at scale without sacrificing performance. Lithium-sulfur batteries demand intricate cathode designs and electrolyte formulations that are robust enough for automotive use. These are not trivial problems and require continuous innovation in process engineering.

Moreover, the supply chain for new materials needed for these batteries must be established and secured. While sulfur is abundant, specific grades and processing methods are necessary. Silicon anode technology relies on high-purity silicon, and solid-state electrolytes may require rare earth elements or novel ceramics. Diversifying and localizing these supply chains, particularly within the US, is a critical strategic imperative to ensure smooth and uninterrupted production as demand escalates.

| Key Technology | Brief Description & Impact |

|---|---|

| Solid-State Batteries | Replaces liquid electrolyte with solid. Offers superior safety, higher energy density, and faster charging for EVs. |

| Silicon Anode Batteries | Uses silicon instead of graphite in anodes, significantly boosting energy density and EV range in the near term. |

| Lithium-Sulfur Batteries | Leverages abundant sulfur for ultra-high energy density, promising extended EV ranges and cost-effectiveness. |

Frequently Asked Questions About EV Battery Breakthroughs

Solid-state batteries offer enhanced safety by eliminating flammable liquid electrolytes, higher energy density for extended range, and the potential for significantly faster charging times compared to current lithium-ion batteries. These advantages make them a highly anticipated development for future electric vehicles.

Silicon anode technology primarily boosts the energy density of existing lithium-ion batteries, leading to increased EV range without major redesigns. Its integration can provide a more immediate performance upgrade for electric vehicles, bridge the gap until solid-state batteries are fully commercialized, and improve charging efficiency.

Yes, lithium-sulfur batteries are considered more environmentally friendly due to their use of abundant and non-toxic sulfur. This reduces reliance on scarce or controversial materials. Their high energy density also means less material is needed per unit of energy, further contributing to sustainability efforts in EV production.

While silicon anode batteries could see more widespread integration by 2025, solid-state batteries are expected to enter high-end EV models around the same time, with broader adoption following. Lithium-sulfur batteries are likely a bit further out, possibly seeing commercial pilot projects by 2025 before more extensive market penetration.

US policies, such as the Inflation Reduction Act, are crucial in incentivizing domestic battery manufacturing and supply chain development. This support accelerates research, development, and scaling of new battery technologies, fostering a competitive environment and ensuring these innovations can be produced and integrated within the US.

Looking Ahead: The Future of EV Power in the US

The rapid pace of innovation in battery technology positions the US at the precipice of a new era for electric vehicles. The developments in solid-state, silicon anode, and lithium-sulfur batteries are not just incremental improvements; they represent foundational shifts that will reshape the automotive industry. As 2025 approaches, the focus remains on overcoming manufacturing hurdles and securing robust supply chains to bring these advancements from the lab to the road. The implications extend beyond just vehicle performance, touching upon energy independence, environmental sustainability, and economic growth. We are witnessing the dawn of truly transformative EV capabilities, and the coming years will be pivotal in realizing their full potential across the nation’s transportation landscape.