Nearshoring for US Auto Manufacturers: 2025 Economic Advantages

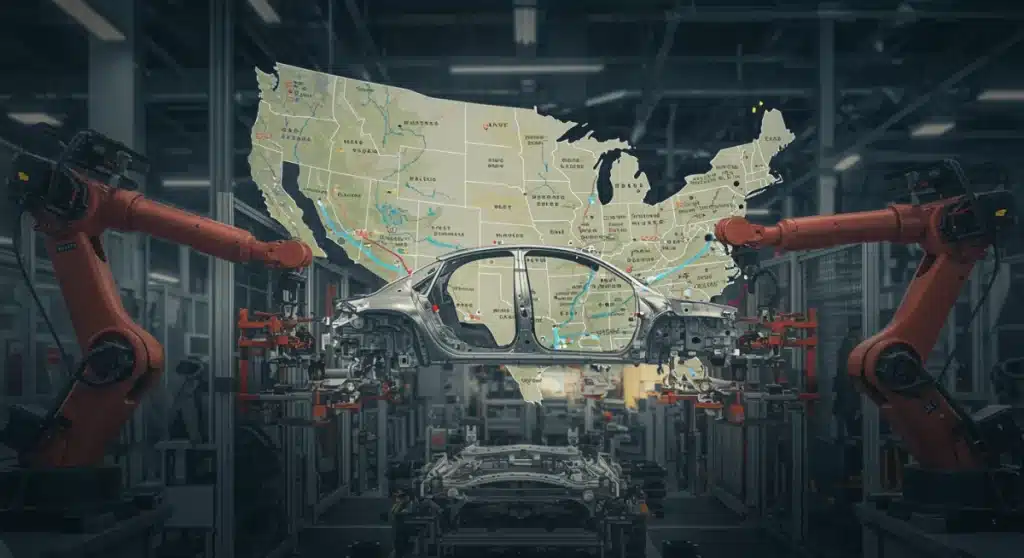

Nearshoring presents significant economic advantages for US auto manufacturers in 2025 by bolstering supply chain stability, cutting operational costs, and accelerating market adaptation, ensuring competitive growth.

The automotive industry is in a state of constant evolution, and understanding The Economic Advantages of Nearshoring for US Auto Manufacturers: A 2025 Perspective is critical for stakeholders. This strategic shift is reshaping how vehicles are produced and delivered, offering a fresh approach to traditional manufacturing models.

As of late 2024, the automotive sector continues to navigate complex global supply chains, geopolitical shifts, and evolving consumer demands. The concept of nearshoring, bringing production closer to the final market, has gained considerable traction. For US auto manufacturers, this strategy is not merely a trend but a calculated move towards greater resilience and profitability. The focus remains on leveraging geographical proximity to optimize operations and mitigate risks that have plagued the industry in recent years. This strategic repositioning is influencing investment decisions and factory locations across North America.

Enhanced Supply Chain Resilience and Stability

The past few years have underscored the fragility of extended global supply chains. US auto manufacturers are increasingly prioritizing stability, and nearshoring provides a robust solution. By relocating production or sourcing closer to home, companies can significantly reduce exposure to international disruptions, ensuring a more consistent flow of components and finished goods.

This shift directly addresses vulnerabilities exposed during recent global crises. Manufacturers are actively seeking ways to safeguard against future unforeseen events, from natural disasters to geopolitical tensions. Nearshoring offers a tangible pathway to achieving this enhanced resilience, creating a more predictable operating environment.

Mitigating Geopolitical Risks and Trade Volatility

- Reduced Exposure to Tariffs: Nearshoring can help companies avoid punitive tariffs and trade barriers imposed on goods from distant regions, leading to more stable import/export costs.

- Fewer Customs Delays: Shorter distances and established regional trade agreements often result in faster customs processing and reduced border delays, improving delivery times.

- Greater Political Stability: Operating within politically stable regions, such as North America, minimizes the risk of sudden policy changes or civil unrest impacting production.

Improved Logistics and Reduced Lead Times

Bringing production closer means a dramatic reduction in transit times. This directly translates to faster inventory replenishment, quicker response to market changes, and a decreased need for large, costly buffer stocks. The efficiency gained in logistics is a cornerstone of nearshoring’s appeal.

Moreover, the environmental footprint associated with transportation is also reduced, aligning with growing corporate sustainability goals. Shorter distances mean less fuel consumption and fewer emissions, presenting an additional benefit beyond pure economic terms. This holistic approach to supply chain optimization is a key driver for many auto manufacturers.

Significant Cost Reductions and Operational Efficiencies

While the initial investment in nearshoring can be substantial, the long-term cost benefits are proving to be a powerful incentive for US auto manufacturers. These savings extend beyond just transportation, encompassing a wider range of operational efficiencies that contribute to a healthier bottom line. The strategic reallocation of resources is yielding tangible financial improvements.

Companies are meticulously analyzing the total cost of ownership, recognizing that lower labor costs in distant regions are often offset by higher shipping expenses, longer lead times, and increased risk. Nearshoring allows for a more holistic view of costs, revealing opportunities for savings that were previously overlooked in traditional offshoring models.

Lower Transportation and Inventory Costs

The most immediate and apparent cost saving from nearshoring is in transportation. Shorter distances mean lower fuel costs, reduced freight charges, and less wear and tear on shipping infrastructure. This directly impacts the cost of goods sold, making products more competitive.

Furthermore, reduced lead times allow for leaner inventory management. Manufacturers can operate with smaller safety stocks, freeing up capital and reducing warehousing expenses. This just-in-time approach, more feasible with nearshoring, minimizes waste and maximizes efficiency throughout the production cycle.

Streamlined Communication and Collaboration

- Real-time Problem Solving: Proximity facilitates quicker communication and collaboration between manufacturing sites, suppliers, and engineering teams, enabling faster resolution of production issues.

- Cultural Alignment: Shared cultural norms and business practices often lead to smoother operational integration and fewer misunderstandings compared to distant offshore partners.

- Easier Oversight: Managers can more easily visit and oversee nearshored facilities, ensuring quality control and adherence to production standards without extensive travel.

The ability to have engineers and production managers on-site quickly to address issues or implement improvements cannot be overstated. This immediate feedback loop accelerates innovation and problem-solving, driving continuous improvement in manufacturing processes. Collaboration becomes seamless, fostering a more agile and responsive production environment.

Enhanced Quality Control and Innovation

One of the less-talked-about, yet highly significant, advantages of nearshoring for US auto manufacturers is the ability to exert greater control over product quality and foster innovation. When production facilities are geographically closer, oversight becomes more direct and effective. This proximity allows for real-time monitoring and immediate corrective actions, leading to superior product outcomes.

The challenges of maintaining consistent quality across vast distances are well-documented. Nearshoring helps bridge this gap, ensuring that manufacturing standards align precisely with corporate expectations. This direct involvement also cultivates an environment ripe for iterative improvements and faster implementation of new technologies.

Direct Oversight and Rapid Problem Solving

With nearshored operations, quality control teams can conduct more frequent and thorough inspections. Any deviations from standards can be identified and rectified almost immediately, preventing minor issues from escalating into major production flaws. This proactive approach minimizes recalls and warranty claims, protecting brand reputation and reducing costs.

The ability to quickly deploy technical experts to a site to troubleshoot problems or optimize processes is invaluable. This agility ensures that production lines remain efficient and that product quality is consistently high. It fosters a culture of continuous improvement, essential in the competitive automotive landscape.

Faster Iteration and Product Development

- Integrated R&D: Nearshoring allows for closer integration between research and development teams and manufacturing facilities, accelerating the transition from prototype to production.

- Market Responsiveness: New product features or design changes can be implemented more quickly in response to market feedback or emerging trends, giving manufacturers a competitive edge.

- Access to Skilled Labor: Proximity to US-based engineering talent pools can facilitate the transfer of knowledge and expertise, driving innovation in manufacturing techniques.

The collaborative environment fostered by nearshoring supports a more agile product development cycle. Design changes, engineering modifications, and new feature integrations can be executed with greater speed and precision. This responsiveness is crucial in an industry where technological advancements and consumer preferences evolve rapidly.

Meeting Evolving Consumer Demands and Sustainability Goals

The modern consumer is not only demanding high-quality vehicles but also increasingly concerned with the environmental and ethical implications of global supply chains. Nearshoring helps US auto manufacturers address both these concerns, aligning their operations with broader societal expectations and market trends. This dual benefit positions companies favorably for future growth.

By shortening supply chains, companies can more easily track and verify sustainable practices among their suppliers. This transparency is becoming a non-negotiable aspect of corporate responsibility, and nearshoring offers a practical framework for achieving it. It’s about building trust with environmentally conscious consumers.

Rapid Response to Market Shifts

The automotive market is dynamic, with consumer preferences shifting rapidly towards electric vehicles, autonomous features, and personalized options. Nearshoring enables manufacturers to adapt quickly to these changes, adjusting production volumes and specifications without the lengthy delays associated with distant supply chains.

This agility is a critical competitive advantage. Companies that can bring new models or updated features to market faster are better positioned to capture market share and meet immediate demand. Nearshoring acts as a catalyst for this responsiveness, turning market trends into tangible product offerings in record time.

Reduced Carbon Footprint and Environmental Impact

- Shorter Transportation Routes: Less distance traveled by components and finished vehicles directly translates to reduced fuel consumption and lower greenhouse gas emissions.

- Local Sourcing Opportunities: Nearshored facilities can more easily source materials and components from local or regional suppliers, further reducing the overall carbon footprint of the supply chain.

- Adherence to Local Regulations: Operating closer to the US market often means adhering to stricter environmental regulations, which can drive cleaner manufacturing processes and sustainable practices.

Sustainability is no longer a niche concern but a core business imperative. Nearshoring offers a tangible way for auto manufacturers to reduce their environmental impact, contributing to a greener future. This commitment resonates with consumers and investors alike, enhancing brand value and attracting environmentally conscious talent.

Job Creation and Economic Stimulus in North America

Beyond the direct benefits to individual companies, nearshoring by US auto manufacturers is poised to deliver significant economic advantages to the broader North American region. This strategic shift involves investing in new facilities, expanding existing ones, and creating a substantial number of jobs across various skill levels. The ripple effect of these investments is profound, stimulating local economies and strengthening regional manufacturing capabilities.

Governments and local communities are actively encouraging nearshoring initiatives through incentives and infrastructure development. The promise of stable, well-paying jobs and increased tax revenues makes this a mutually beneficial strategy. It’s a reinvestment in the continent’s industrial base.

Boosting Local Economies and Employment

New manufacturing plants and expanded operations require a diverse workforce, from skilled technicians and engineers to administrative staff and logistics personnel. This job creation directly boosts local employment rates and provides economic stability to communities that host these facilities. The influx of new jobs often leads to increased consumer spending and local business growth.

The revitalization of manufacturing sectors also encourages educational institutions to tailor programs that meet the industry’s evolving needs, creating a pipeline of skilled workers. This symbiotic relationship between industry and education ensures a sustainable workforce for the future, further solidifying the economic benefits of nearshoring.

Strengthening Regional Manufacturing Ecosystems

- Supply Chain Integration: Nearshoring encourages the development of a more integrated regional supply chain, fostering collaboration and growth among local component suppliers and service providers.

- Knowledge Transfer: The establishment of advanced manufacturing facilities facilitates the transfer of cutting-edge technologies and best practices across the regional industrial base.

- Increased Investment: As more auto manufacturers nearshore, it attracts further investment in related industries, creating a virtuous cycle of economic growth and specialization within the region.

The development of robust regional manufacturing ecosystems makes the entire North American automotive industry more competitive on a global scale. By clustering expertise and resources, companies can achieve greater efficiencies and drive innovation more effectively. This collective strength benefits all participants, from large manufacturers to small local businesses.

Future Outlook: Capitalizing on Nearshoring in 2025

As 2025 approaches, US auto manufacturers are increasingly positioned to fully capitalize on the strategic advantages offered by nearshoring. The foundational investments and shifts in operational philosophy are beginning to yield tangible results, setting the stage for a more resilient and competitive industry. The lessons learned from past disruptions are informing future strategies, emphasizing agility and localized control.

The automotive landscape continues to evolve, with technological advancements and sustainability mandates driving significant changes. Nearshoring provides a framework that allows manufacturers to embrace these changes proactively, rather than reactively. This forward-looking approach is crucial for long-term success in a rapidly transforming global market.

Strategic Investments and Policy Support

Governments in North America are recognizing the strategic importance of strengthening domestic and regional manufacturing. This recognition is translating into supportive policies, incentives, and infrastructure investments that further enhance the attractiveness of nearshoring. These collaborative efforts are essential for sustaining momentum.

Manufacturers are also making significant capital expenditures in modernizing facilities and adopting advanced manufacturing technologies, such as automation and artificial intelligence. These investments are not just about relocating production but about upgrading the entire manufacturing process to be more efficient, sustainable, and responsive.

Long-Term Competitiveness and Adaptability

- Reduced Dependence: Nearshoring lessens reliance on potentially volatile distant supply chains, providing greater control and predictability over production schedules and costs.

- Market Proximity: Being closer to the consumer market allows for quicker adaptation to changing tastes and regulatory requirements, maintaining a competitive edge.

- Sustainable Growth: The environmental and social benefits of nearshoring contribute to a stronger brand image and long-term sustainable growth, appealing to a broader base of stakeholders.

The long-term vision for US auto manufacturers involves building an industry that is not only robust against external shocks but also highly adaptable to future challenges and opportunities. Nearshoring is a cornerstone of this vision, enabling a proactive stance in an increasingly complex global economy. It’s about securing a prosperous future for automotive manufacturing in North America.

| Key Advantage | Brief Description |

|---|---|

| Supply Chain Resilience | Reduces exposure to global disruptions and geopolitical risks, ensuring consistent component flow. |

| Cost Efficiency | Lowers transportation, inventory, and logistics costs, contributing to a healthier financial outcome. |

| Quality & Innovation | Enables direct oversight, faster problem-solving, and quicker iteration in product development. |

| Market Responsiveness | Allows rapid adaptation to consumer demands and environmental goals with reduced lead times. |

Frequently Asked Questions About Nearshoring in Auto Manufacturing

Nearshoring involves relocating manufacturing operations or sourcing components to geographically closer countries, typically Mexico or Canada for US auto manufacturers. This strategy aims to reduce logistical complexities and improve supply chain efficiency compared to traditional offshoring to distant regions.

By bringing production closer, automakers reduce their exposure to international disruptions like geopolitical conflicts, trade wars, or natural disasters. This proximity ensures a more stable and predictable flow of parts and finished vehicles, minimizing costly delays and production halts.

The main cost benefits include significantly lower transportation expenses due to shorter distances, reduced inventory holding costs from faster lead times, and fewer tariffs or trade barriers. These savings collectively improve the overall profitability and competitiveness of nearshored operations.

Yes, nearshoring allows for more direct oversight and immediate problem-solving on the factory floor. This close collaboration fosters faster iteration in product development, enabling quicker implementation of design changes and new technologies, ultimately leading to higher quality and more innovative vehicles.

Nearshoring stimulates job creation by requiring new manufacturing facilities and expanded operations, boosting local employment. It also strengthens regional manufacturing ecosystems by encouraging investment, fostering supply chain integration, and facilitating knowledge transfer across North America, driving broader economic growth.

Looking Ahead: The Future of Auto Manufacturing

The strategic shift towards nearshoring represents a fundamental re-evaluation of global manufacturing models for US auto manufacturers. As 2025 unfolds, expect to see continued investments in regional production capabilities and a further solidification of North American supply chains. This movement is not merely a response to past crises but a proactive strategy to build a more agile, cost-effective, and sustainable automotive industry. The focus remains on leveraging proximity to foster innovation, enhance quality, and meet the evolving demands of a rapidly changing market, ensuring long-term competitiveness and resilience for the sector.