New EPA Emissions Standards 2025: US Automakers’ Compliance

Latest developments on the new EPA Emissions Standards for 2025 reveal significant changes for US automakers, impacting vehicle production and technological innovation. This article outlines key requirements and industry adjustments now.

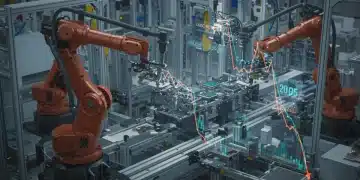

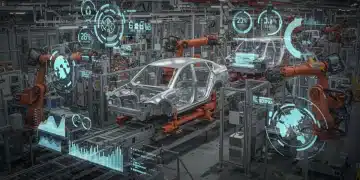

2025 EPA Emissions Standards: Impact on US Auto Manufacturing Costs

New 2025 EPA emissions standards are projected to increase US auto manufacturing costs by 10%, significantly impacting vehicle production, pricing, and strategic shifts towards cleaner technologies.

2025 EV Fleet Benefits: Saving Businesses $1,000+ Per Vehicle Annually

Businesses adopting EV fleets by 2025 stand to save over $1,000 per vehicle annually, driven by lower operational costs, government incentives, and reduced maintenance, according to recent industry analyses.

Biometric Security in Vehicles: US Automotive Access & Theft Prevention by 2025

Biometric security in vehicles is rapidly advancing, poised to redefine US automotive access and significantly enhance theft prevention by 2025 through technologies like fingerprint and facial recognition.

Quantum Computing’s Role in Automotive Design: 2025 Outlook

By 2025, quantum computing is poised to revolutionize automotive design, offering US engineering teams unprecedented capabilities for materials science, optimization, and complex simulations, fundamentally reshaping vehicle development processes.

2025 US Auto Paint Tech: Latest Innovations & Updates

The latest innovations in automotive paint technology for US-made vehicles in 2025 are revolutionizing durability, sustainability, and aesthetic possibilities, driven by advanced materials and smart applications to meet evolving consumer demands and regulatory standards.