Supply Chain Issues and Car Delivery Delays in the Auto Industry

Supply chain issues continue to plague the auto industry, leading to significant delays in new car deliveries. Shortages of essential components, such as semiconductors, are impacting production schedules and pushing back delivery timelines for consumers.

The automotive industry is still grappling with significant disruptions. Supply chain issues continue to plague the auto industry, presenting ongoing challenges for manufacturers and impacting consumers eager to receive their new vehicles. These disruptions, stemming from a confluence of factors, are leading to extended wait times and uncertainty in the market.

Understanding the Root Causes of Auto Industry Supply Chain Issues

The global automotive industry relies on a complex and interconnected network of suppliers, spanning various continents and specialties. Recent years have exposed the fragility of this network, revealing how easily disruptions can cascade through the entire system. Several key factors are contributing to supply chain issues continue to plague the auto industry.

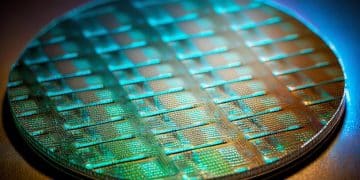

The Semiconductor Shortage: A Critical Bottleneck

Semiconductors, or microchips, are essential components in modern vehicles, controlling everything from engine management to infotainment systems. A surge in demand for semiconductors during the pandemic, coupled with existing manufacturing capacity constraints, created a severe shortage that continues to impact automotive production. The inability to source these chips has forced manufacturers to idle plants and reduce output.

Geopolitical Instability and Trade Disruptions

Geopolitical tensions and trade disputes further complicate the automotive supply chain. Tariffs, sanctions, and other trade barriers can disrupt the flow of essential materials and components, adding costs and delays. Uncertainties surrounding international relations make it difficult for companies to plan and invest in long-term sourcing strategies.

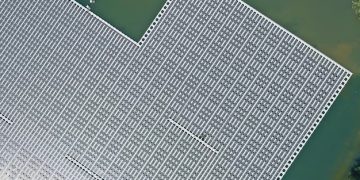

- Raw Material Scarcity: Limited availability of raw materials like lithium, cobalt, and nickel, crucial for battery production, poses a long-term challenge.

- Logistics Congestion: Port congestion and shipping delays add to the overall time it takes to move components from suppliers to manufacturing plants.

- Labor Shortages: Constraints in the labor market, particularly in transportation and warehousing, further exacerbate logistical challenges.

In conclusion, the automotive industry’s ongoing supply chain problems are the result of a complex interplay of global factors, including a shortage of semiconductors, geopolitical instability, and logistical congestion. These forces create significant challenges for manufacturers striving to meet consumer demand and deliver new cars on time.

The Impact on New Car Deliveries and Consumer Experience

Supply chain issues continue to plague the auto industry, and the impact is particularly felt by consumers eagerly awaiting their new vehicles. The delays and uncertainties surrounding delivery timelines have led to frustration and a diminished customer experience. Many dealerships struggle to provide accurate ETAs, leaving buyers in the dark about when they can expect to receive their cars.

Extended wait times are becoming the norm. What was once a few weeks can now stretch into months, or even longer, for popular models or those with specific options. This can be especially frustrating for buyers who need a vehicle urgently or have planned their finances around a specific delivery date.

Higher Prices and Reduced Incentives

The scarcity of new cars has driven up prices and reduced manufacturers’ incentive to offer discounts or rebates. With demand exceeding supply, dealerships have less reason to negotiate, and many are adding markups to MSRP. This makes new vehicles less affordable for many consumers.

Changes in Vehicle Specifications and Options

To work around supply chain bottlenecks, some manufacturers are temporarily altering vehicle specifications or removing certain options. For example, some cars may be shipped without certain features or with substitute components. While this allows production to continue, it can be disappointing for buyers who had specific requirements in mind.

Ultimately, the supply chain issues continue to plague the auto industry has resulted in a less satisfying buying experience for consumers. From longer wait times and higher prices to changes in vehicle specifications, the disruptions have reshaped the market and tested the patience of car buyers.

Strategies Auto Manufacturers Are Employing to Mitigate Delays

Faced with persistent supply chain issues continue to plague the auto industry, automotive manufacturers are implementing various strategies to mitigate disruptions and improve delivery timelines. These efforts include diversifying sourcing, increasing inventory, and strengthening relationships with suppliers. These strategies aim to build resilience and improve the industry’s ability to weather future challenges.

Diversifying Sourcing and Building Redundancy

Relying on a single supplier for critical components can create vulnerabilities in the supply chain. Manufacturers are increasingly diversifying their supplier base, identifying alternative sources for essential materials and parts. This reduces dependence on any one source and provides a buffer against disruptions.

Increasing Inventory and Buffer Stock

Maintaining larger inventories of key components can help manufacturers weather temporary supply disruptions. By building a buffer stock, companies can continue production even if certain supplies are delayed. This strategy requires careful planning and investment in warehousing and logistics.

- Nearshoring and Reshoring: Bringing production closer to home can improve supply chain visibility and reduce reliance on distant suppliers.

- Strengthening Supplier Relationships: Building stronger relationships with key suppliers fosters better communication and collaboration.

- Investing in Technology: Implementing advanced supply chain management software and analytics tools can improve forecasting and enable better decision-making.

By implementing these approaches, automotive manufacturers aim to minimize the impact of supply chain issues continue to plague the auto industry and keep their production lines running smoothly. These strategies are essential for building a more resilient and agile supply chain in the face of ongoing global challenges.

Forecasting the Future: When Will the Auto Industry Supply Chain Normalize?

Predicting the timeline for the auto industry’s supply chain to normalize is challenging. Several factors influence the restoration of stability, including the resolution of the semiconductor shortage, the easing of geopolitical tensions, and improvements in global logistics. While some experts anticipate gradual improvements, the consensus is that disruptions will persist for the foreseeable future. Supply chain issues continue to plague the auto industry with no near end in sight.

Semiconductor Production Capacity Expansion

Substantial investments are being made to expand semiconductor manufacturing capacity. These investments will gradually alleviate the shortage, but new facilities typically take several years to become fully operational. As new capacity comes online, the availability of chips should improve, but the process will be gradual.

Geopolitical Developments and Trade Policies

Changes in geopolitical relations and trade policies could significantly impact the automotive supply chain. A reduction in trade tensions and the removal of tariffs could improve the flow of materials and components. However, ongoing uncertainties make it difficult to predict the impact of these factors.

For end consumers, continue to expect potential delays when ordering a new car. The supply chain issues continue to plague the auto industry cannot be resolved immediately.

Overall, the outlook for the normalization of the automotive supply chain remains uncertain. While some improvements are expected, significant challenges persist. Manufacturers and consumers alike should prepare for continued disruptions and adjust their expectations accordingly.

Consumer Strategies for Navigating New Car Delivery Delays

Given the ongoing supply chain issues continue to plague the auto industry, consumers can take several steps to navigate new car delivery delays effectively: Consider pre-ordering, staying flexible on vehicle options, and exploring alternative transportation solutions. These strategies can help mitigate frustration and ensure access to reliable transportation.

Plan Ahead and Pre-Order Early

Anticipating the need for a vehicle and placing a pre-order well in advance can improve the chances of receiving the desired model in a timely manner. This provides manufacturers and dealerships with better visibility into demand and allows them to plan production and allocate resources accordingly. Early planning is crucial to minimize the impact of delivery delays.

Be Flexible on Vehicle Options and Features

Being open to alternative vehicle options and features can also expedite the delivery process. Some configurations may be more readily available than others due to variations in component availability. By being flexible, consumers can increase the likelihood of finding a vehicle that meets their needs without excessive delays.

- Consider alternative vehicles: Research makes and models that meet your needs.

- Communicate often with dealerships: Check on order status and delivery estimates.

- Be ready to act quickly: Don’t delay making a decision when a vehicle becomes available.

By adopting these strategies, consumers can navigate the challenges of new car delivery delays more effectively. Remaining proactive, informed, and flexible can help mitigate frustration and ensure access to reliable transportation despite ongoing disruptions.

In summary, navigating car delivery delays due to supply chain issues requires being proactive, flexible, and well-informed. Consumers who plan ahead, remain open to alternatives, and maintain clear communication with dealerships are better positioned to weather these challenges.

| Key Point | Brief Description |

|---|---|

| ⚠️ Semiconductor Shortage | Limits car production due to chip unavailability. |

| 🚢 Logistics Congestion | Port delays increase delivery times for new vehicles. |

| 💰 Higher Car Prices | Limited supply drives up the cost of new cars. |

| 🗓️ Delivery Delays | Consumers face extended wait times for the car. |

Frequently Asked Questions

The primary reasons include a global semiconductor shortage, geopolitical instability, and logistical bottlenecks. These factors disrupt the production and delivery of essential car components.

Wait times vary, but expect potentially months. Demand, model popularity, and chosen options all influence wait duration. Check with your dealership.

Yes, models requiring many semiconductors or specific parts are more susceptible. Luxury vehicles and those with advanced tech features are examples.

Consider pre-ordering early, being flexible with options, and maintaining open communication with your dealership. Explore available inventory as well.

They are diversifying sourcing, increasing inventories, and strengthening supplier relationships. These strategies aim to mitigate disruptions and improve stability for production in the future.

Conclusion

In conclusion, supply chain issues continue to plague the auto industry, causing significant delays for new car deliveries. While manufacturers are actively working to mitigate these disruptions and consumer strategies can help minimize impact. It’s important to stay informed, plan ahead, and remain flexible when navigating the current landscape of the automotive market.