US Auto Plant Expansions: 2025 Job Growth & Economic Impact

The financial impact of US automotive plant expansions, including 2025 job growth projections, is a critical driver of economic development, creating thousands of new manufacturing positions and stimulating local economies across the nation.

US auto plant jobs are at the forefront of a significant economic transformation as automotive manufacturers continue to invest heavily in expanding their footprint across the nation. This surge in investment is not merely about increasing production capacity; it is fundamentally reshaping local economies, creating new employment opportunities, and bolstering the United States’ position in the global automotive landscape. This report delves into the tangible financial impact and the projected job growth for 2025, providing a clear picture of what lies ahead.

The Current Landscape of Automotive Plant Investments

The US automotive sector is experiencing an unprecedented wave of investment, driven largely by the transition to electric vehicles (EVs) and renewed focus on domestic manufacturing. Major automakers and battery producers are committing billions of dollars to construct new facilities and significantly expand existing ones.

These investments are concentrated in key regions, often referred to as the ‘Battery Belt’ or ‘EV Hubs,’ stretching across the Southeast and Midwest. States like Georgia, Tennessee, Kentucky, and Michigan are seeing massive capital injections, which are expected to translate directly into substantial job creation and economic uplift. The scale of these projects underscores a long-term commitment to US-based production, moving beyond traditional internal combustion engine manufacturing.

Billions Poured into New Facilities

- Ford Motor Company: Investing over $11 billion in new EV and battery manufacturing campuses in Tennessee and Kentucky, creating approximately 11,000 new jobs.

- General Motors: Partnering with LG Energy Solution for battery cell plants in Ohio, Tennessee, and Michigan, with investments totaling billions and thousands of anticipated jobs.

- Stellantis: Committing significant capital to revamp existing plants for EV production and establish new battery facilities, particularly in Indiana, creating thousands of positions.

These figures represent a fraction of the total investment, as numerous other companies, including Hyundai, Toyota, and various battery component suppliers, are also making substantial commitments. The cumulative effect of these investments is a robust pipeline of projects set to come online or ramp up production by 2025, directly influencing the job market.

The current landscape indicates a strategic shift towards self-sufficiency in critical components, particularly batteries, and a move away from reliance on overseas supply chains. This trend is further supported by government incentives aimed at boosting domestic production and ensuring the US remains competitive in the evolving global automotive industry. These expansions are not just about manufacturing vehicles, but also about building an entire ecosystem around new automotive technologies.

Projected Job Growth by 2025: A Detailed Outlook

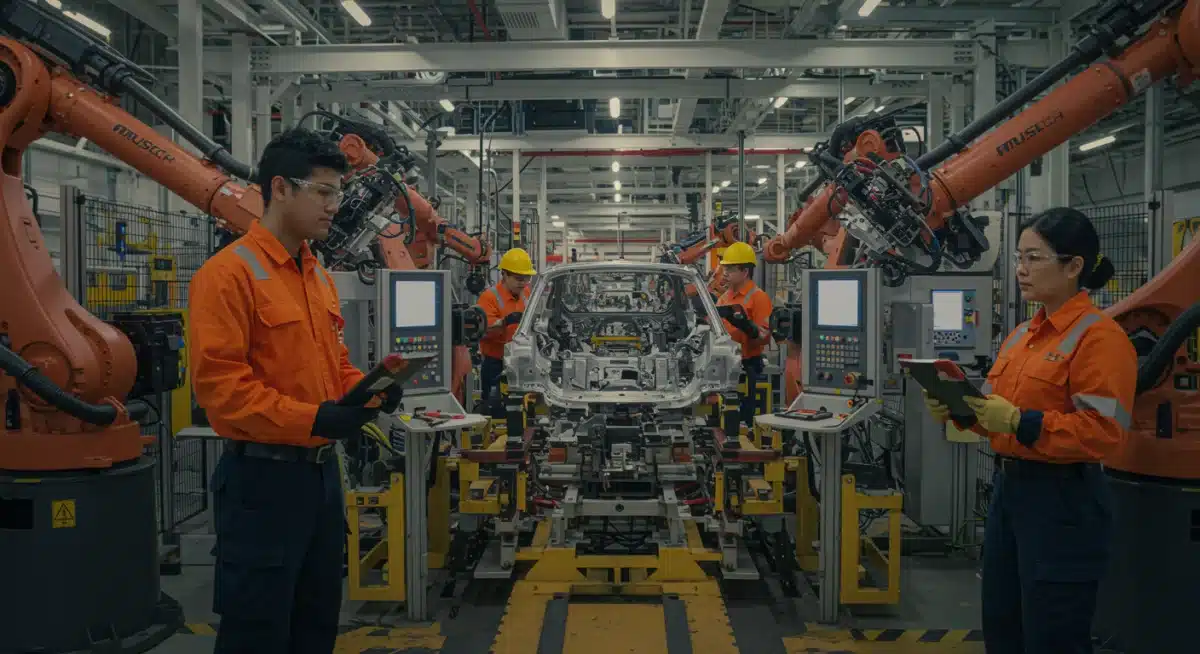

The financial impact of US automotive plant expansions directly translates into significant job growth. Analysts and industry reports project tens of thousands of new direct manufacturing jobs by 2025, with an even greater multiplier effect on indirect and induced employment.

Direct jobs include roles on the assembly line, in engineering, quality control, logistics, and plant management. These are often well-paying positions that offer competitive benefits, contributing to a stronger middle class in the regions where these plants are located. The shift to EV production also demands new skill sets, leading to increased demand for training and educational programs.

Direct Job Creation Estimates

- Manufacturing Roles: Expectations are for 75,000 to 100,000 new direct manufacturing jobs across various automotive and battery plant sites.

- Engineering and R&D: A rise in specialized engineering positions for battery technology, software integration, and advanced manufacturing processes.

- Skilled Trades: Increased demand for electricians, mechanics, welders, and maintenance technicians to support complex plant operations.

Beyond direct employment, the ripple effect of these expansions is substantial. For every direct manufacturing job created, an estimated three to five additional jobs are generated in supporting industries. This includes construction, transportation, raw materials supply, local services, and retail.

By 2025, these indirect and induced jobs could add another 200,000 to 500,000 positions nationwide. This comprehensive job growth picture highlights the profound economic stimulus provided by these automotive investments. States actively competing for these plants often emphasize the long-term employment benefits as a primary justification for tax incentives and infrastructure development.

Economic Multiplier Effect: Beyond Direct Employment

The economic benefits of US automotive plant expansions extend far beyond the direct jobs created within the factories themselves. The multiplier effect describes how initial spending and job creation generate additional economic activity throughout a region and the nation.

When a new automotive plant is built or expanded, it requires significant investment in construction, materials, and equipment. This immediately boosts the construction sector and industries supplying steel, concrete, and advanced machinery. Once operational, the plant regularly purchases raw materials, components, and services from a network of suppliers, creating jobs and economic activity in those supplier companies.

Key Areas of Multiplier Impact

- Supply Chain Expansion: New demands for battery components, semiconductors, specialized plastics, and metals drive investment and hiring in upstream industries.

- Service Sector Growth: Increased population and higher wages lead to greater demand for housing, retail, healthcare, education, and entertainment in surrounding communities.

- Infrastructure Development: State and local governments often invest in roads, utilities, and public services to support the new industrial sites and growing populations.

The infusion of new wages into local economies also stimulates consumption. Employees spend their earnings on goods and services, supporting local businesses and generating tax revenue. This increased spending further circulates within the economy, leading to additional job creation in various sectors.

For example, a typical automotive assembly plant can support dozens of smaller businesses, from logistics firms transporting parts to catering services feeding plant workers. This intricate web of economic interdependence ensures that the benefits of automotive plant expansions are widely distributed, making them powerful engines for regional economic development.

Regional Economic Development and Community Impact

The US auto plant jobs generated by new and expanded facilities are fundamentally transforming regional economic landscapes. Communities that secure these investments often experience rapid growth, accompanied by both opportunities and challenges.

An influx of well-paying manufacturing jobs can revitalize struggling towns, increase property values, and boost local tax revenues. These revenues can then be reinvested in schools, public services, and infrastructure, creating a positive feedback loop for community development. The presence of a major automotive plant often attracts other businesses, leading to further diversification of the local economy.

Transformative Community Benefits

- Revitalization of Local Economies: Increased employment and higher wages stimulate local businesses and attract new investments.

- Enhanced Public Services: Higher tax revenues can fund improvements in education, healthcare, and public safety.

- Workforce Development: New plants often partner with local educational institutions to develop specialized training programs, upgrading local skill sets.

However, rapid growth also presents challenges. Increased demand for housing can lead to affordability issues, and existing infrastructure may struggle to keep pace with population growth. Communities must carefully plan for these changes, ensuring sustainable development that benefits all residents.

Despite these challenges, the long-term economic stability and opportunity offered by these automotive investments are overwhelmingly positive. They represent a chance for regions to adapt to the changing manufacturing landscape and secure their economic future in the era of electric vehicles and advanced production technologies. Local governments are actively working with developers to mitigate negative impacts and maximize positive outcomes.

Challenges and Opportunities in Workforce Development

The rapid expansion of US automotive plants, particularly those focused on electric vehicles and advanced manufacturing, presents both significant challenges and unique opportunities for workforce development. The demand for skilled labor is outpacing the current supply, necessitating innovative approaches to training and recruitment.

The transition from traditional internal combustion engine production to EV manufacturing requires a new set of skills, including expertise in battery technology, power electronics, software integration, and advanced robotics. Many existing workers need retraining, while new entrants to the workforce require specialized education.

Addressing the Skill Gap

- Industry-Academia Partnerships: Collaboration between automakers, community colleges, and universities to develop tailored curricula and apprenticeship programs.

- Upskilling and Reskilling Initiatives: Programs designed to retrain current automotive workers for new roles in EV and battery production.

- Attracting New Talent: Efforts to draw younger generations and diverse populations into manufacturing careers through outreach and STEM education.

States and federal agencies are investing in workforce development programs to bridge this skill gap. Apprenticeships, vocational training, and community college programs are becoming crucial pipelines for preparing the next generation of automotive workers. This collaborative effort is essential to ensure that the projected US auto plant jobs can be filled by a qualified workforce.

Furthermore, diversity and inclusion initiatives are gaining traction to ensure that the new jobs are accessible to a broad range of individuals, fostering a more equitable and robust workforce. The opportunity lies in creating a highly skilled, adaptable labor force capable of driving innovation and maintaining global competitiveness in the automotive sector.

Future Outlook and Long-Term Financial Impact

Looking beyond 2025, the long-term financial impact of US automotive plant expansions appears robust and transformative. These investments are laying the groundwork for a more resilient, technologically advanced, and domestically focused automotive industry.

The move towards localized production, particularly for critical EV components like batteries, reduces reliance on volatile international supply chains and enhances national economic security. This strategic shift is expected to create sustained job growth and economic stability for decades to come, positioning the US as a leader in future automotive technologies.

Sustained Growth and Innovation

- Technological Advancements: Continued investment in R&D within these plants will drive innovation in EV technology, autonomous driving, and sustainable manufacturing practices.

- Supply Chain Resilience: A stronger domestic supply chain will buffer against global disruptions, ensuring more stable production and employment.

- Export Opportunities: Increased production capacity could lead to greater export opportunities for US-made vehicles and components, boosting national trade balances.

The sustained economic activity generated by these plants will continue to fuel regional development, creating vibrant industrial ecosystems. This includes not only direct suppliers but also research institutions, logistics providers, and various support services that cluster around major manufacturing hubs.

The long-term outlook suggests that the financial impact of US automotive plant expansions will be a cornerstone of the nation’s economic strategy, contributing significantly to GDP, fostering innovation, and securing high-quality manufacturing jobs for future generations. Policy support, continued private investment, and a focus on workforce development will be crucial to realizing this potential fully.

Key Point |

Brief Description > |

|---|---|

Investment Surge |

Billions invested by automakers in new EV and battery plants across US. |

2025 Job Growth |

Projected tens of thousands of direct manufacturing jobs, plus hundreds of thousands of indirect jobs. |

Economic Multiplier |

Each direct job supports 3-5 additional jobs in supply chain and service sectors. |

Workforce Development |

Demand for new skills drives industry-academia partnerships and retraining initiatives. |

Frequently Asked Questions About US Auto Plant Expansions

The primary drivers are the rapid shift to electric vehicle (EV) production, the need for domestic battery manufacturing, and government incentives aimed at bolstering US manufacturing and reducing reliance on foreign supply chains.

Industry analysts project between 75,000 and 100,000 new direct manufacturing jobs, with an additional 200,000 to 500,000 indirect and induced jobs across supporting industries and local economies by 2025.

Significant investments are concentrated in the ‘Battery Belt’ and ‘EV Hubs’ across the Southeast and Midwest, including states like Georgia, Tennessee, Kentucky, Michigan, and Indiana, transforming their industrial landscapes.

New roles require expertise in battery technology, power electronics, software integration, advanced robotics, and specialized skilled trades. There is a strong emphasis on upskilling and reskilling existing workforces and training new entrants.

Long-term benefits include enhanced supply chain resilience, sustained job growth, increased GDP contribution, technological innovation, and a stronger US position in the global automotive market, fostering robust regional development.

What this means

The ongoing expansion of US automotive plants signifies a pivotal moment for the nation’s economy and manufacturing sector. These investments are not just about producing more vehicles; they represent a fundamental retooling of the industrial base, creating a new generation of US auto plant jobs and fostering innovation. For communities, this means significant economic stimulus and the potential for long-term prosperity. Stakeholders across government, industry, and education must continue to collaborate to maximize these opportunities, ensuring a skilled workforce and sustainable growth as the automotive landscape continues its rapid evolution.