Major US Automaker’s Q4 2025 Production Boost Strategy Revealed

An exclusive interview provides insider knowledge on a major US automaker’s strategy for a significant Q4 2025 production boost, detailing critical initiatives and forward-looking plans for the automotive market.

An Exclusive Interview: A Major US Automaker’s Strategy for Q4 2025 Production Boost (INSIDER KNOWLEDGE) reveals ambitious plans set to reshape the industry landscape. This deep dive uncovers the core initiatives, technological advancements, and strategic partnerships driving this anticipated surge, offering crucial insights for stakeholders and enthusiasts alike.

Unveiling the Q4 2025 Production Boost Roadmap

The automaker’s strategy centers on a multi-faceted approach designed to significantly increase output by the end of 2025. This roadmap emphasizes efficiency, innovation, and strategic resource allocation to meet growing market demands and maintain a competitive edge.

Key executives, speaking under condition of anonymity to provide candid insights, detailed how this production boost is not merely about volume but also about enhancing product quality and sustainability. The plans are a direct response to evolving consumer preferences and the need for greater resilience in global supply chains.

Strategic Pillars of Expansion

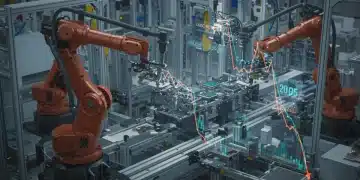

- Advanced Manufacturing Techniques: Implementation of AI-driven automation and robotics across assembly lines to streamline processes and reduce human error.

- Supply Chain Fortification: Diversification of suppliers and localized sourcing to mitigate risks and ensure a steady flow of critical components.

- Workforce Development: Significant investment in training and upskilling programs for existing employees, alongside aggressive recruitment of specialized talent in areas like software and battery technology.

- Sustainable Practices: Integration of eco-friendly materials and energy-efficient processes throughout the manufacturing cycle to reduce environmental impact.

The strategic pillars underpinning this production boost are meticulously planned to address both immediate operational needs and long-term market trends. This holistic approach aims to create a more robust and adaptable manufacturing ecosystem.

Technological Innovations Driving Efficiency

Central to the Q4 2025 production boost is the widespread adoption of cutting-edge technologies. These innovations are not just theoretical; they are being actively integrated into every stage of the manufacturing process, from design to final assembly.

The automaker is leveraging advanced analytics and machine learning to predict potential bottlenecks and optimize production schedules. This data-driven approach allows for proactive adjustments, minimizing downtime and maximizing throughput. The goal is to create a ‘smart factory’ environment where every component and process is interconnected and continuously optimized.

Key Technological Implementations

- AI-Powered Robotics: Deployment of collaborative robots (cobots) working alongside human operators, enhancing precision and speed.

- Digital Twin Technology: Creation of virtual models of physical production lines to simulate scenarios, test improvements, and identify efficiencies before real-world implementation.

- Internet of Things (IoT): Integration of sensors across machinery and components to provide real-time data on performance, maintenance needs, and inventory levels.

- Additive Manufacturing: Increased use of 3D printing for prototyping and producing specialized parts, reducing lead times and material waste.

These technological advancements are expected to yield significant gains in both the speed and quality of production, positioning the automaker at the forefront of manufacturing innovation. The investment in these areas reflects a long-term commitment to operational excellence.

Supply Chain Resilience and Localization Efforts

The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting a strategic re-evaluation within the automotive industry. This major US automaker has made supply chain resilience a cornerstone of its Q4 2025 strategy, focusing heavily on localization and diversification.

The objective is to reduce dependence on single-source suppliers, particularly those located in geopolitically sensitive regions. By fostering stronger relationships with domestic and nearshore suppliers, the automaker aims to create a more stable and predictable flow of components, shielding production from future disruptions.

This shift also involves significant investment in supplier development programs, ensuring that local partners can meet the stringent quality and volume requirements necessary for a major production boost. The emphasis is on building a robust network that can adapt quickly to changing market conditions.

Critical Supply Chain Initiatives

- Regional Hub Development: Establishing regional manufacturing and assembly hubs closer to key markets, reducing transportation costs and lead times.

- Dual Sourcing Strategies: Implementing policies to have at least two qualified suppliers for every critical component, minimizing the impact of any single supplier failure.

- Vertical Integration: Exploring opportunities for in-house production of certain high-value or strategically important components, such as battery cells or advanced semiconductors.

- Predictive Analytics for Logistics: Utilizing AI to forecast demand fluctuations and potential logistical challenges, enabling proactive adjustments to inventory and shipping.

These efforts are designed to create a more agile and resilient supply chain, capable of supporting the ambitious Q4 2025 production targets while ensuring consistent quality and availability.

Workforce Development and Talent Acquisition

A successful production boost is intrinsically linked to a skilled and motivated workforce. Recognizing this, the automaker is investing heavily in both upskilling its current employees and attracting new talent, particularly in emerging technological fields.

Training programs are being rolled out across all manufacturing facilities, focusing on areas such as advanced robotics operation, data analytics, and electric vehicle component assembly. These programs are designed to equip the workforce with the necessary skills to operate and maintain the sophisticated new machinery being introduced.

Furthermore, the company is actively collaborating with educational institutions to develop specialized curricula that align with future industry needs. This partnership aims to create a pipeline of qualified graduates ready to contribute to the automotive sector.

Key Workforce Strategies

- Apprenticeship Programs: Expanding vocational training and apprenticeship opportunities to develop hands-on expertise in critical manufacturing roles.

- Digital Literacy Initiatives: Providing training to enhance employees’ understanding and proficiency in digital tools and software used in modern manufacturing.

- Recruitment Drives for STEM Talent: Aggressively recruiting engineers, data scientists, and software developers to drive innovation in product development and manufacturing processes.

- Employee Engagement and Retention: Implementing programs to foster a positive work environment, offer competitive benefits, and provide clear career progression paths to retain top talent.

The emphasis on human capital development underscores the understanding that technology alone cannot deliver the desired production boost; it requires a highly skilled and adaptable workforce to truly thrive.

Market Impact and Competitive Landscape

The planned Q4 2025 production boost is expected to have significant repercussions across the automotive market. Increased output from a major US automaker could intensify competition, influence pricing strategies, and potentially shift market share.

Analysts anticipate that this surge in production will primarily target high-demand segments, particularly electric vehicles (EVs) and advanced utility vehicles. By increasing availability, the automaker aims to capture a larger portion of these rapidly expanding markets, challenging both traditional rivals and emerging players.

The move is also seen as a strategic response to global economic uncertainties, with the automaker positioning itself to capitalize on any potential economic upturn. A strong domestic production base provides a hedge against international trade fluctuations and strengthens national economic contributions.

Anticipated Market Effects

- Increased Vehicle Availability: Shorter waiting times for popular models, potentially reducing dealer markups.

- Competitive Pricing: Greater supply could lead to more competitive pricing, benefiting consumers.

- Innovation Acceleration: The push for higher production often drives further innovation in manufacturing processes and vehicle technology.

- Economic Stimulus: Increased manufacturing activity is expected to create jobs and stimulate economic growth in regions with production facilities.

The ripple effects of this production strategy will extend beyond the automaker itself, influencing suppliers, dealerships, and even the broader economic landscape, creating a dynamic period for the US automotive sector.

Sustainability and Future-Proofing Production

Beyond sheer volume, the automaker’s Q4 2025 strategy places a strong emphasis on sustainability, recognizing its importance for brand image, regulatory compliance, and long-term operational viability. This commitment to eco-friendly practices is integrated throughout the production boost plan.

Efforts include transitioning to renewable energy sources for manufacturing facilities, minimizing waste through advanced recycling programs, and designing vehicles with materials that are easier to recycle or are derived from sustainable sources. The aim is to achieve a net-zero carbon footprint in manufacturing operations.

This focus on sustainability also extends to product development, with a clear push towards electric and hybrid vehicles that offer lower emissions and greater energy efficiency for consumers. The automaker views sustainability not just as a compliance issue, but as a core competitive advantage in the modern market.

Key Sustainability Initiatives

- Renewable Energy Adoption: Investing in solar and wind power for factories, reducing reliance on fossil fuels.

- Waste Reduction Programs: Implementing lean manufacturing principles to minimize material waste and enhance recycling efforts across all facilities.

- Eco-Friendly Material Sourcing: Prioritizing suppliers who use sustainable practices and provide recyclable or bio-based materials for vehicle components.

- Water Conservation: Implementing advanced water treatment and recycling systems in manufacturing plants to reduce overall water consumption.

By embedding sustainability into the very fabric of its production strategy, the automaker is not only future-proofing its operations but also appealing to a growing segment of environmentally conscious consumers.

Key Strategy |

Brief Description |

|---|---|

Production Boost |

Ambitious plan for significant output increase by Q4 2025, focusing on efficiency and quality. |

Technological Integration |

Extensive use of AI, robotics, digital twins, and IoT for optimized manufacturing. |

Supply Chain Resilience |

Localization, diversification, and dual sourcing to mitigate risks and ensure component flow. |

Workforce Development |

Upskilling current employees and attracting new talent for advanced manufacturing roles. |

Frequently Asked Questions About the Q4 2025 Production Boost

The primary goal is to significantly increase vehicle output by the end of 2025. This boost aims to meet rising market demand, particularly for electric vehicles, while simultaneously enhancing product quality and manufacturing sustainability through advanced processes and strategic resource allocation.

Central technologies include AI-driven automation, advanced robotics, digital twin technology for virtual simulations, and the Internet of Things (IoT) for real-time data collection. These innovations are integrated to optimize efficiency, predict bottlenecks, and streamline the entire manufacturing process.

The automaker is fortifying its supply chain through extensive localization efforts and diversification strategies. This involves building stronger relationships with domestic suppliers, implementing dual-sourcing policies for critical components, and exploring vertical integration to reduce reliance on single-source foreign providers.

Workforce development is crucial. The strategy includes significant investments in upskilling current employees in areas like robotics and data analytics, alongside aggressive recruitment of specialized talent. This ensures the workforce is equipped to handle advanced manufacturing technologies and supports long-term operational success.

The production boost is expected to increase vehicle availability, potentially leading to more competitive pricing and shifting market shares, especially in the EV sector. It will also accelerate innovation within the industry and provide a significant economic stimulus through job creation and increased manufacturing activity.

Looking Ahead

The revealed strategy for a Q4 2025 production boost signals a pivotal moment for this major US automaker and the broader automotive industry. The blend of technological innovation, supply chain resilience, and human capital development positions the company for significant growth. Monitoring the implementation of these initiatives, particularly in supply chain adjustments and workforce integration, will be key to understanding the full impact on vehicle availability, market competition, and the industry’s sustainable future. This ambitious plan sets a new benchmark for manufacturing excellence and market responsiveness.