Regulatory Shifts 2025: EPA Emissions Impact on US EV Manufacturing

As the automotive industry accelerates its transition, the upcoming Regulatory Shifts in 2025: How New EPA Emissions Standards Impact EV Manufacturing in the US (RECENT UPDATES) are poised to redefine the landscape for electric vehicle production. These changes aren’t just about cleaner air; they signal a profound transformation in how EVs are designed, built, and brought to market across the United States. What do these stringent new rules mean for American automakers and consumers?

Understanding the New EPA Emissions Standards for 2025

The Environmental Protection Agency (EPA) has finalized new, more stringent emissions standards for model years 2027 through 2032, building upon the framework set for 2025. These regulations aim to significantly reduce greenhouse gas emissions from new light-duty and medium-duty vehicles, effectively pushing automakers towards a greater adoption of electric vehicles. This move represents a critical step in the Biden administration’s broader climate agenda, intending to accelerate the nation’s shift away from fossil fuels.

The core of these new standards involves a phased approach to emissions reduction. While the 2025 targets are already in motion, the recently announced rules for later years solidify the trajectory for the industry. Automakers must meet fleet-wide average emissions targets, making it increasingly difficult to do so without a substantial portion of their sales coming from zero-emission vehicles. This regulatory pressure is designed to spur innovation and investment in EV technology and manufacturing capabilities within the US.

Key Components of the Latest EPA Rules

The EPA’s updated regulations are multifaceted, touching upon various aspects of vehicle production and sales. They establish a clear pathway for emissions reductions over the next decade, providing automakers with a predictable regulatory environment for long-term planning.

- Stricter Tailpipe Emissions Limits: The new rules mandate significant reductions in tailpipe emissions, making it challenging for internal combustion engine (ICE) vehicles to meet compliance without hybridization or electrification.

- Increased EV Adoption Targets: While not explicitly mandating EV sales percentages, the stringency of the emissions targets effectively necessitates a substantial increase in EV production and sales to achieve compliance.

- Flexibility Mechanisms: The EPA has included provisions such as emissions credits, allowing manufacturers to bank, trade, or transfer credits to meet compliance, offering some flexibility in the transition period.

These components collectively paint a picture of an automotive future heavily reliant on electric propulsion. The regulations are a direct response to climate change concerns and global efforts to decarbonize transportation, placing the US at a pivotal juncture in this global shift.

Direct Impact on US EV Manufacturing Operations

The new EPA emissions standards for 2025 and beyond are poised to have a profound and immediate impact on electric vehicle manufacturing operations across the United States. Automakers are already re-evaluating their production strategies, supply chains, and investment priorities to align with these ambitious targets. This regulatory push is not just about meeting compliance; it’s about seizing the opportunity to establish the US as a global leader in EV production.

Domestic manufacturing facilities are expected to see significant upgrades and expansions. Companies like General Motors, Ford, and Stellantis, alongside newer EV players like Tesla and Rivian, are investing billions into retooling existing plants and constructing new ones dedicated to EV battery and vehicle assembly. This surge in investment is critical for creating a robust domestic EV supply chain, reducing reliance on foreign components, and boosting American jobs.

Investment in Production Facilities

The need to scale up EV production to meet the anticipated demand driven by EPA regulations is leading to unprecedented investment in manufacturing infrastructure. This includes not only final assembly plants but also facilities for battery cell production, electric motor manufacturing, and other critical EV components.

- Gigafactories for Batteries: Several new battery manufacturing plants are under construction or planned across states like Georgia, Michigan, and Kentucky, forming the backbone of the domestic EV supply chain.

- Retooling Traditional Plants: Many legacy automakers are converting their existing internal combustion engine (ICE) vehicle plants into EV production hubs, preserving jobs and leveraging existing infrastructure.

- Advanced Robotics and Automation: Manufacturing processes are becoming increasingly automated to enhance efficiency, precision, and scalability in EV production.

These investments are vital for the US to compete effectively in the global EV market, ensuring that American-made electric vehicles are cost-competitive and technologically advanced. The regulatory framework acts as a powerful catalyst for this industrial transformation.

Supply Chain Challenges and Opportunities for EVs

The ramp-up in EV manufacturing, directly influenced by the 2025 EPA emissions standards, brings both significant challenges and unparalleled opportunities for the US automotive supply chain. The shift from traditional gasoline-powered vehicles to electric ones requires a completely different set of raw materials, components, and manufacturing processes. Securing a stable and ethical supply of critical minerals, such as lithium, cobalt, and nickel, is paramount to meeting production targets.

Currently, a substantial portion of these critical minerals and their processing capabilities reside outside the United States. This presents a vulnerability but also an immense opportunity for domestic mining, refining, and recycling industries to emerge and grow. Building a resilient, localized supply chain for EVs is a strategic imperative for national economic security and environmental goals.

Developing Domestic Sourcing for Critical Minerals

The push for increased EV production necessitates a strong focus on domestic sourcing to mitigate geopolitical risks and ensure sustainability. Efforts are underway to identify and develop new mineral deposits within the US and to invest in advanced recycling technologies to recover valuable materials from end-of-life batteries.

This includes partnerships between government and private industry, providing incentives for domestic extraction and processing. The goal is to reduce dependence on foreign adversaries for key components, creating a more secure and environmentally responsible supply chain. The EPA’s regulations indirectly support this by accelerating EV demand, making domestic supply chain investments more economically viable.

Technological Innovations Driven by Regulatory Pressure

The stringent EPA emissions standards for 2025 are acting as a powerful accelerant for technological innovation within the electric vehicle sector. Automakers and their suppliers are under immense pressure to develop more efficient, affordable, and high-performing EVs to meet both regulatory requirements and consumer demand. This environment fosters breakthroughs in battery technology, charging infrastructure, and vehicle design.

One of the primary areas of innovation is in battery chemistry and packaging, aimed at increasing energy density, reducing charging times, and extending battery life. Beyond the battery, advancements in electric motor design, power electronics, and thermal management systems are crucial for maximizing vehicle efficiency and range. Software development also plays a critical role, enhancing everything from energy management to autonomous driving capabilities.

Advancements in Battery Technology and Charging

Batteries remain the heart of any EV, and continuous innovation in this area is key to widespread adoption. The regulatory landscape encourages faster development and deployment of next-generation battery technologies, such as solid-state batteries, which promise greater safety, energy density, and faster charging.

- Solid-State Batteries: Research and development are intensely focused on bringing solid-state battery technology to commercial viability, offering superior performance characteristics.

- Ultra-Fast Charging Networks: Investment in and development of more robust and widespread public charging infrastructure, including DC fast chargers, are essential to alleviate range anxiety and support EV growth.

- Vehicle-to-Grid (V2G) Technology: Innovations are also extending to how EVs interact with the power grid, enabling them to serve as mobile energy storage units and enhance grid stability.

These technological leaps are not just about meeting regulations; they are about making EVs more attractive and practical for the average consumer, driving broader market acceptance. The EPA’s standards provide a clear incentive for these innovations to move from the lab to the production line rapidly.

Economic Implications for the US Automotive Sector

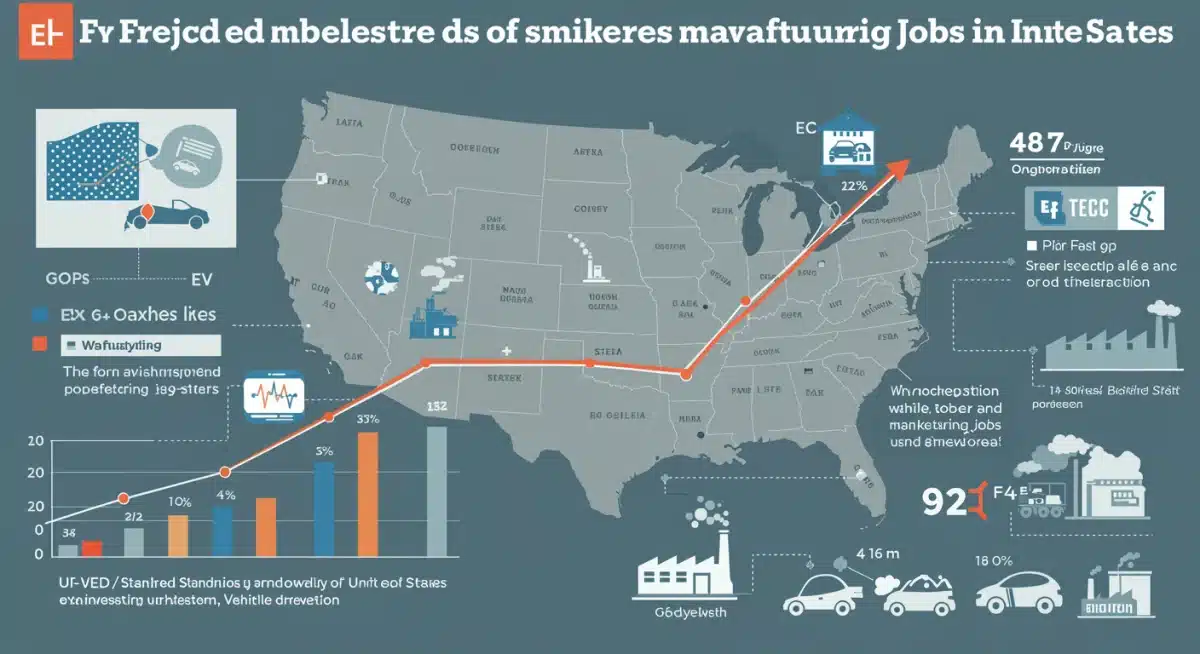

The economic ramifications of the EPA Emissions EV Manufacturing standards for 2025 are far-reaching, influencing job creation, trade balances, and overall economic growth within the US automotive sector. While the transition to EVs requires significant upfront investment, it also promises long-term economic benefits, including the creation of new high-tech manufacturing jobs and a reduction in reliance on volatile global oil markets.

The shift is fostering a new industrial ecosystem, from raw material extraction to advanced software development. This reorientation of the automotive industry is expected to stimulate regional economies, particularly in states that are attracting major EV and battery manufacturing facilities. The competitive landscape among states vying for these investments is intense, as each seeks to capitalize on the economic boom.

Job Creation and Workforce Adaptation

The transition to EV manufacturing will undoubtedly lead to a shift in the types of jobs available in the automotive sector. While some traditional roles may diminish, there will be a significant increase in demand for skilled workers in areas such as battery engineering, power electronics, software development, and advanced manufacturing.

This necessitates substantial investment in workforce training and education programs to equip the current and future labor force with the skills required for the EV era. Government initiatives, alongside private sector partnerships, are crucial for facilitating this transition and ensuring that American workers are prepared for the jobs of tomorrow.

Consumer Adoption and Market Dynamics Under New Standards

The EPA’s 2025 emissions standards are designed to significantly influence consumer adoption of electric vehicles by increasing the availability of diverse and more affordable EV models. As automakers ramp up production to meet regulatory targets, the market is expected to see a greater variety of electric cars, trucks, and SUVs, catering to a wider range of consumer preferences and budgets. This expansion of choice, combined with ongoing advancements in battery range and charging infrastructure, is crucial for accelerating the transition to electric mobility.

Beyond vehicle availability, the standards indirectly encourage competitive pricing. As manufacturers scale up production, economies of scale can lead to lower manufacturing costs, which can then be passed on to consumers. Furthermore, continued federal and state incentives, such as tax credits for EV purchases, will play a vital role in making electric vehicles more financially appealing to the broader public, complementing the regulatory push.

Factors Influencing Consumer EV Choices

Several key factors will continue to shape consumer decisions regarding EV adoption, all of which are indirectly bolstered by the new regulatory environment. Understanding these dynamics is essential for automakers and policymakers alike to ensure a smooth and rapid transition.

- Purchase Price and Total Cost of Ownership: The upfront cost of EVs compared to ICE vehicles remains a significant consideration, though lower fuel and maintenance costs often lead to a lower total cost of ownership over time.

- Charging Infrastructure Accessibility: The availability and reliability of public and home charging solutions are critical for widespread adoption, addressing consumer concerns about range anxiety.

- Vehicle Performance and Range: Continuous improvements in battery technology, leading to longer ranges and better performance, are making EVs more appealing for daily commutes and longer trips.

The interplay of these factors, combined with the regulatory imperative, is creating a dynamic market where EVs are becoming an increasingly viable and attractive option for American consumers. The EPA’s standards are not just about emissions; they are about shaping the future of transportation choices.

Global Competitiveness and International Cooperation

The Regulatory Shifts in 2025: How New EPA Emissions Standards Impact EV Manufacturing in the US (RECENT UPDATES) also have significant implications for the United States’ position in the global automotive landscape. By setting ambitious emissions reduction targets, the EPA is signaling a strong commitment to electric vehicles, which can enhance the US’s competitiveness in the rapidly growing global EV market. This aggressive stance encourages domestic innovation and production, potentially establishing the US as a leader in EV technology and manufacturing processes.

However, global competitiveness also hinges on international cooperation. Harmonizing standards with other major automotive markets, such as Europe and China, can streamline manufacturing processes, reduce complexity for multinational corporations, and facilitate global trade in EVs and their components. This collaboration is essential to address shared challenges, such as critical mineral supply chains and the development of universal charging standards, fostering a more interconnected and efficient global EV ecosystem.

Challenges and Opportunities in Global Trade

The new standards present both challenges and opportunities regarding international trade. While they aim to boost domestic production, they could also influence import and export dynamics for vehicles and components. Balancing the need for domestic growth with the benefits of global trade will be a key consideration for policymakers.

- Export Potential: A strong domestic EV manufacturing base can position the US to export advanced EVs and related technologies to other markets.

- Import Considerations: The standards may influence the types of vehicles imported into the US, favoring those that meet or exceed the new emissions requirements.

- International Partnerships: Collaborations with international partners on research, development, and supply chain management can accelerate technological advancements and share the burden of investment.

Ultimately, the US’s ability to navigate these global dynamics will determine the full extent of the economic and environmental benefits derived from the 2025 EPA emissions standards. Engagement with international bodies and trading partners will be crucial for maximizing these opportunities and addressing potential hurdles.

| Key Point | Brief Description |

|---|---|

| New EPA Standards | Stricter emissions targets for 2027-2032, building on 2025, pushing rapid EV adoption. |

| US Manufacturing Impact | Billions invested in new EV and battery plants, retooling existing facilities, boosting domestic production. |

| Supply Chain Shift | Focus on domestic sourcing for critical minerals and components to reduce foreign reliance. |

| Technological Innovation | Regulations drive advancements in battery tech, charging infrastructure, and vehicle design. |

Frequently Asked Questions About EPA Emissions and EV Manufacturing

The primary goals are to significantly reduce greenhouse gas emissions from light-duty and medium-duty vehicles, accelerate the transition to electric vehicles (EVs), and improve air quality. These standards aim to drive technological innovation and boost domestic EV manufacturing capabilities.

US EV manufacturing will see increased investment in new factories and retooling of existing ones for EV and battery production. Automakers are expanding capacity, creating new jobs, and focusing on localized supply chains to meet the anticipated demand driven by regulatory pressure and consumer interest.

Key challenges include securing a stable and ethical supply of critical minerals like lithium and cobalt. Opportunities arise for domestic mining, refining, and recycling industries to emerge, reducing reliance on foreign sources and building a more resilient, localized EV supply chain.

Indirectly, yes. By driving increased production and fostering economies of scale, the standards can lead to lower manufacturing costs, which may translate into more competitive pricing for consumers. This effect is often coupled with federal and state incentives to boost affordability.

The ambitious US standards aim to position the country as a leader in EV technology and manufacturing, enhancing global competitiveness. They also encourage international cooperation on harmonized standards and supply chain solutions, fostering a more integrated global EV market.

What Happens Next

The implementation of the 2025 EPA emissions standards marks a pivotal moment for the US auto industry. Automakers will continue to refine their strategies, investing heavily in R&D and manufacturing capabilities to meet the stringent targets. We anticipate further announcements on new factory openings, expanded production lines, and technological breakthroughs in battery and charging solutions. The coming months will also reveal how consumer demand adapts to the growing EV market, influenced by both regulatory incentives and infrastructure development. Policy adjustments and international collaborations will remain key areas to watch as the nation drives towards a fully electric future.