2025 EV Battery Recycling: US 95% Recovery Goal Analysis

The United States is aggressively pursuing a 95% recovery rate for valuable materials from electric vehicle batteries by 2025, initiating comprehensive recycling programs to support a sustainable EV ecosystem.

As the electric vehicle (EV) market rapidly expands, the imperative for robust recycling infrastructure becomes paramount. Analyzing 2025 EV Battery Recycling Programs: Recovering 95% of Valuable Materials in the US (COMPARISON/ANALYSIS) reveals a critical juncture in sustainable automotive development. The US is pushing for an ambitious 95% recovery target for key materials from spent EV batteries, a goal that demands significant innovation and collaboration across industries.

The Ambitious 95% Recovery Target: A National Imperative

The United States has set a bold target: to recover 95% of valuable materials from electric vehicle batteries by 2025. This objective is not merely aspirational; it is a strategic move to secure critical mineral supplies, reduce environmental impact, and foster a circular economy within the burgeoning EV sector. Achieving this goal requires a multi-faceted approach, integrating advanced technological solutions, supportive policies, and robust public-private partnerships.

Driving Forces Behind the Target

Several factors underscore the urgency and importance of the 95% recovery target. Global competition for scarce resources and the geopolitical implications of mineral supply chains are significant drivers. Domestically, the rapid adoption of EVs translates into a growing volume of end-of-life batteries, necessitating efficient recycling solutions to prevent landfill waste and maximize resource utilization.

- Resource Security: Reducing reliance on foreign sources for critical minerals like lithium, cobalt, and nickel.

- Environmental Stewardship: Minimizing the ecological footprint associated with battery production and disposal.

- Economic Opportunity: Creating new industries and jobs in battery recycling and material re-manufacturing.

- Supply Chain Resilience: Building a more robust and sustainable domestic supply chain for EV components.

This aggressive target signals a clear commitment from the US government to lead in sustainable EV technology and resource management, positioning the nation as a key player in the global battery economy.

Current Landscape of EV Battery Recycling in the US

The current state of EV battery recycling in the US presents a mix of emerging technologies and established practices, all working towards the ambitious 95% recovery goal. Several companies and research institutions are pioneering methods to efficiently extract valuable materials from spent batteries, addressing both economic viability and environmental responsibility.

Presently, recycling efforts are primarily focused on high-value materials such as cobalt and nickel, with increasing attention on lithium recovery. The processes typically involve either pyrometallurgy, which uses high heat, or hydrometallurgy, which employs chemical solutions to separate and purify materials. Both methods have their advantages and disadvantages in terms of cost, efficiency, and environmental impact.

Key Players and Initiatives

Numerous entities are actively engaged in developing and scaling up EV battery recycling operations. These include established recycling companies, battery manufacturers, and automotive giants, often in collaboration with government-funded research programs. The Department of Energy’s ReCell Center, for instance, is a national collaboration dedicated to advancing battery recycling technologies.

- Li-Cycle: Utilizes hydrometallurgical processes to recover up to 95% of materials, focusing on a hub-and-spoke model.

- Redwood Materials: Founded by Tesla co-founder JB Straubel, aims for a closed-loop supply chain, recovering over 95% of materials.

- Umicore: A global leader with a presence in the US, employing proprietary technologies for efficient material recovery.

These initiatives are crucial for building the necessary infrastructure and expertise to meet the 2025 target. The development of advanced sorting and processing techniques is vital to handle the diverse chemistries and designs of modern EV batteries.

Technological Innovations Driving Higher Recovery Rates

Achieving a 95% recovery rate for valuable materials from EV batteries necessitates continuous technological innovation. Researchers and companies are developing new methods and refining existing ones to improve efficiency, reduce costs, and minimize environmental footprints. These advancements are critical for transforming battery recycling from a niche activity into a mainstream industrial process.

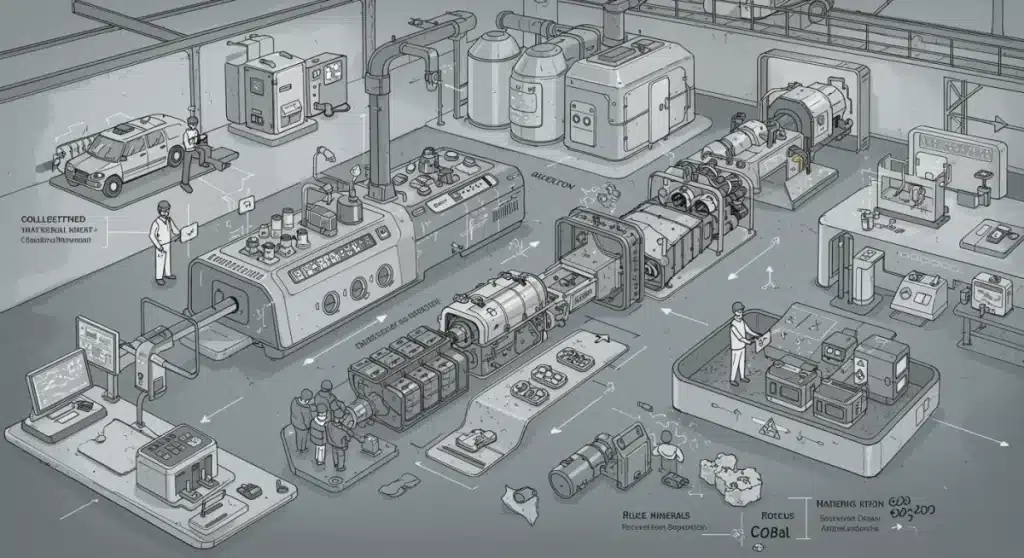

One primary area of innovation involves enhancing the pre-treatment and dismantling stages of recycling. Automation and robotics are being integrated to safely and efficiently disassemble battery packs, separating components for further processing. This reduces manual labor and improves safety, while also increasing the purity of sorted materials, which is crucial for high-efficiency recovery processes.

Advanced Recycling Methods

Beyond traditional pyrometallurgy and hydrometallurgy, novel approaches are gaining traction. Direct recycling, for example, aims to preserve the cathode structure, thus reducing the energy and resource intensity of re-manufacturing. This method holds promise for higher material retention and lower costs, though it requires precise sorting and handling of battery chemistries.

- Direct Recycling: Preserves the cathode material’s structure, reducing energy consumption and cost.

- Electrochemical Processes: Uses electrical currents to selectively recover metals, offering higher purity.

- Bio-leaching: Utilizes microorganisms to extract metals, providing a more environmentally friendly alternative.

These innovations are not just about recovering more material; they are also about recovering higher quality materials that can be directly re-integrated into new battery production, thereby closing the loop more effectively. The focus is on processes that are both economically viable and environmentally sustainable.

Policy and Regulatory Frameworks Supporting Recycling

Robust policy and regulatory frameworks are indispensable for supporting and enforcing the ambitious 95% recovery target for EV battery materials in the US. Government intervention is crucial to stimulate investment, standardize processes, and create a level playing field for recycling companies. Without clear guidelines and incentives, the transition to a fully circular battery economy would be significantly hampered.

Federal initiatives, such as the Bipartisan Infrastructure Law, allocate substantial funding towards battery recycling research, development, and infrastructure. These investments aim to accelerate the deployment of advanced recycling technologies and establish a robust domestic supply chain for critical battery materials. State-level policies also play a role, often complementing federal efforts with local incentives and regulations.

Key Policy Drivers

Several legislative and regulatory actions are shaping the future of EV battery recycling. These include mandates for battery collection, extended producer responsibility (EPR) schemes, and research grants. The goal is to ensure that manufacturers and consumers are actively involved in the recycling process, from design to end-of-life management.

- Infrastructure Investments: Funding for new recycling facilities and R&D through federal programs.

- Extended Producer Responsibility (EPR): Holding manufacturers accountable for the entire lifecycle of their products.

- Material Labeling Standards: Facilitating easier identification and sorting of battery chemistries for recyclers.

The ongoing development of these frameworks is essential to create a predictable and supportive environment for the recycling industry. Consistent policy signals encourage long-term investments and foster innovation, ultimately contributing to the attainment of the 95% recovery goal.

Economic Viability and Market Dynamics

The economic viability of EV battery recycling is a critical factor influencing its widespread adoption and the achievement of the 95% recovery target. While the environmental benefits are clear, the financial incentives must also align to create a sustainable industry. Market dynamics, including material prices, processing costs, and government subsidies, all play a significant role in determining profitability.

Currently, the market for recycled battery materials is influenced by the fluctuating prices of virgin minerals. When virgin material prices are high, recycling becomes more attractive. However, advancements in recycling technologies are steadily reducing processing costs, making recycled materials competitive even when virgin prices are lower. This trend is crucial for ensuring long-term economic stability for the recycling sector.

Cost-Benefit Analysis

A comprehensive cost-benefit analysis reveals that while initial investments in recycling infrastructure can be substantial, the long-term returns are significant. These returns include reduced dependence on volatile global supply chains, creation of domestic jobs, and avoidance of environmental remediation costs associated with improper disposal. Government incentives are often necessary to bridge the gap during the early stages of market development.

- Reduced Virgin Material Costs: Less reliance on primary mining, stabilizing supply.

- New Revenue Streams: Sale of recovered materials and recycling services.

- Environmental Compliance: Avoiding penalties and promoting corporate social responsibility.

The evolving market for recycled materials, coupled with increasing demand for EVs, suggests a positive outlook for the economic viability of battery recycling. Companies that can efficiently recover high-purity materials at competitive costs will be well-positioned for success.

Challenges and Future Outlook for 2025

Despite the ambitious goals and significant progress, several challenges remain in achieving the 95% recovery target for EV battery materials by 2025. These hurdles span technological, logistical, and regulatory domains, requiring concerted efforts from all stakeholders to overcome. Addressing these challenges is paramount for the long-term success of sustainable EV battery management in the US.

One major challenge is the sheer diversity of EV battery chemistries and designs. Different manufacturers use varying cell formats and materials, complicating standardized recycling processes. The rapid evolution of battery technology also means that recycling facilities must be adaptable and capable of handling future battery generations, which adds complexity to infrastructure planning and investment.

Overcoming Obstacles

Logistical complexities also pose a significant barrier. Collecting, transporting, and storing spent EV batteries safely and efficiently across a vast country like the US requires a well-coordinated network. The high voltage and hazardous nature of these batteries demand specialized handling and transportation protocols, adding to operational costs.

- Battery Diversity: Standardizing recycling processes for various chemistries and designs.

- Logistical Infrastructure: Developing efficient collection and transportation networks.

- Regulatory Harmonization: Ensuring consistent policies across states and federal agencies.

- Consumer Awareness: Educating the public on the importance and process of battery recycling.

Looking ahead to 2025, continuous investment in R&D, coupled with strong policy support and industry collaboration, will be crucial. The progress made in the next few years will largely determine whether the US can indeed meet its ambitious recycling targets and establish a truly circular economy for electric vehicles.

| Key Point | Brief Description |

|---|---|

| 95% Recovery Target | US goal to recover 95% of valuable materials from EV batteries by 2025, driven by resource security and environmental goals. |

| Current Recycling Methods | Focus on pyrometallurgy and hydrometallurgy, with companies like Li-Cycle and Redwood Materials leading efforts. |

| Technological Innovations | Advancements in direct recycling, electrochemical processes, and bio-leaching to improve efficiency and purity. |

| Policy Support | Federal laws and initiatives, such as the Bipartisan Infrastructure Law, provide funding and frameworks for recycling. |

Frequently Asked Questions About EV Battery Recycling

The main goal is to achieve a 95% recovery rate of valuable materials from electric vehicle batteries by 2025. This aims to enhance resource security, reduce environmental impact, and foster a circular economy for critical minerals.

Key materials targeted for recovery include lithium, cobalt, nickel, and manganese. These elements are crucial for new battery production and are often subject to supply chain vulnerabilities, making recycling essential.

The primary methods are pyrometallurgy, which uses high heat, and hydrometallurgy, which employs chemical solutions to extract materials. Direct recycling and bio-leaching are also emerging as promising, more sustainable alternatives.

Government policies, including the Bipartisan Infrastructure Law, provide funding for R&D and infrastructure. Extended Producer Responsibility (EPR) schemes and material labeling standards also encourage responsible recycling practices across the industry.

Challenges include the diversity of battery chemistries, the need for robust logistical infrastructure for collection and transport, and ensuring continuous technological innovation to handle evolving battery designs efficiently and economically.

Looking Ahead: Impact and Implications

The drive to achieve a 95% recovery rate for EV battery materials by 2025 represents far more than a technical milestone—it signals a national strategic shift in how the United States approaches resource sovereignty, circular manufacturing, and long-term industrial competitiveness. Beyond securing domestic access to critical minerals like lithium, cobalt, and nickel, this goal underscores a broader effort to reduce dependency on international extraction chains and realign the value creation process within US borders.

If executed successfully, this initiative will serve as a catalyst for advanced recycling ecosystems, enabling not just material recovery, but the creation of new industrial clusters centered around battery refurbishment, secondary-use applications, and closed-loop production cycles. The rise of specialized partners in this space, such as services dedicated to lithium-ion battery recycling, exemplified por plataformas como Battery Recyclers of America, illustrates how a new industrial supply chain is emerging around sustainability and material recovery efficiency.

This coordinated effort stands to generate high-skilled jobs, inspire new clean-tech startups, and position the United States as a global leader in sustainable manufacturing intelligence. As electric mobility scales, battery recovery and mineral recirculation will become as strategically important as battery production itself. Ultimately, the success of this initiative will not only reduce environmental impact but also define the next phase of economic power in the EV era, giving the US a decisive edge in innovation, policy leadership, and green industrialization on the world stage.